TM 5-2420-230-24-2

Accessories - Removal (0-36)

Section 0 - Engine Disassembly and Assembly - Group 00

Page 0-24

B Series Shop Manual

Accessories - Removal (0-36)

10 mm, 14 mm, 18 mm

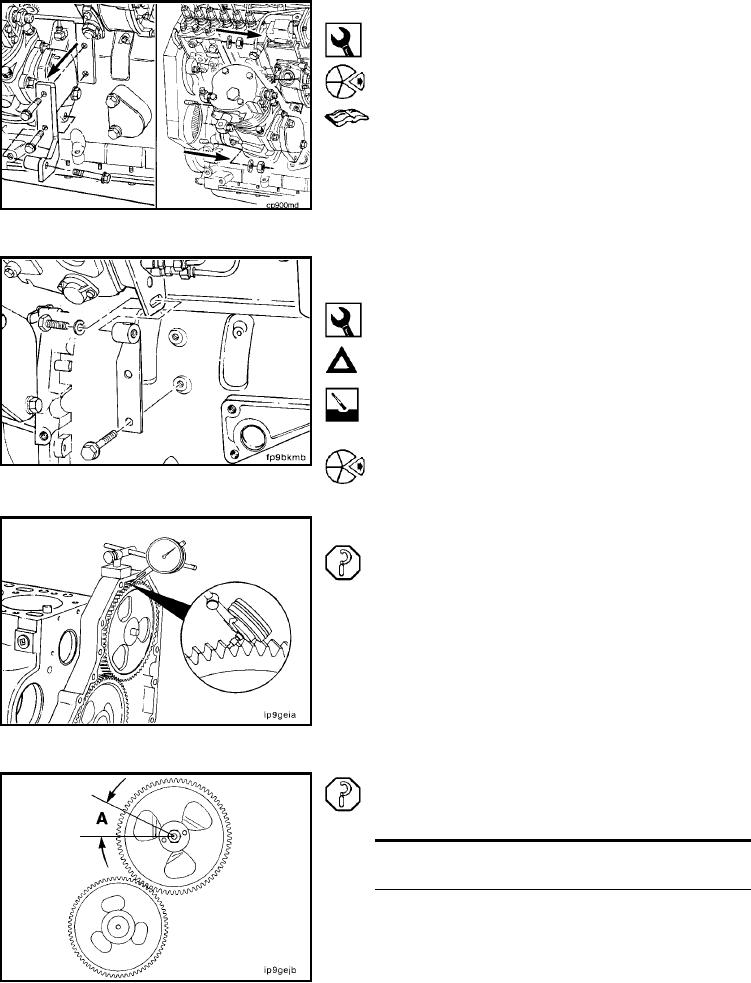

If equipped, remove all additional gear driven accesso-

ries, (air compressor, hydraulic pump, etc.).

NOTE: Refer to the Manufacturer's Service Information for

repair instructions.

Injection Pump - Removal (Rotary Type

Pumps) (0-37)

13 mm

Caution: A diesel engine cannot tolerate dirt or water in

the fuel system. A tiny piece of dirt or a few drops of

water in the injection system can cause damage to the

system.

Clean all external surfaces of the injection pump, includ-

ing all line connections and fittings that are to be discon-

nected. Clean the area around the injection pump gear

cover to prevent dirt from entering the crankcase.

Remove the injection pump support bracket and

capscrews.

Gear Lash - Check (0-38)

Position an indicator on the tooth of the injection pump

drive gear.

Note the total indicator travel as injection pump drive gear

backlash. Mark the pump drive gear and camshaft gear

for further analysis if the backlash exceeds the limits.

Injection Pump Drive Gear

Backlash Limit (A)

mm

in

0.076

MIN

0.003

0.330

MAX

0.013

NOTE: Prevent movement of adjoining gear when checking

backlash or the reading will be the total of both gears.

L-113