TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Piston (001-043)

Section 1 - Cylinder Block - Group 01

Page 1-83

Test (001-043-012)

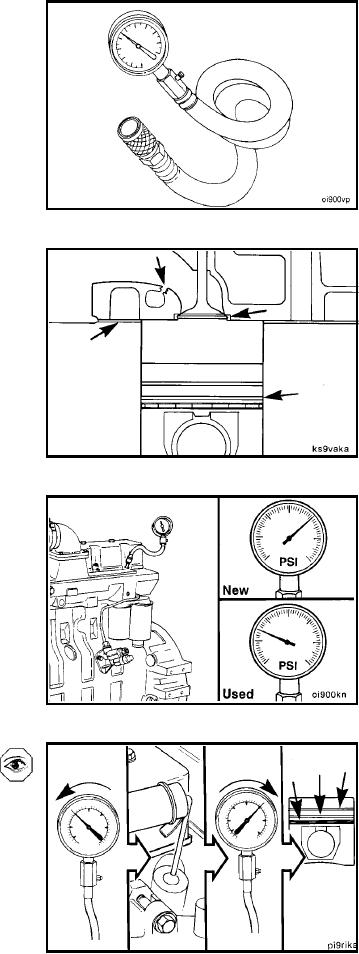

Compression Gauge and Adapter

It is very time consuming and expensive to begin removing

internal engine components to diagnose failures. A com-

pression gauge can be used as an aid to detect failures.

Compression Check

If the air and fuel system are functioning correctly, perform

a compression check to determine whether the problem is:

Piston ring sealing

Valve sealing

Cylinder head gasket sealing or a crack in the cyl-

inder head.

NOTE: Due to variables such as; starter and battery con-

ditions that affect engine cranking speed, it is difficult to

establish an absolute value for compression pressure; how-

ever, the following values can be used as guidelines:

New engine (cranking speed @ 250 rpm) 2413 kPa

[350 psi]

Used engine (cranking speed @ 250 rpm) 2068 kPa

[300 psi].

It is recommended that the compression pressure be

checked and compared on all cylinders. All cylinders should

be within 690 kPa [100 psi] of each other.

Piston Ring Sealing

If the compression is low but can be increased significantly

by squirting lubricating oil into the cylinder, the cause of low

compression is inadequate sealing between the piston rings

and the cylinder walls.

L-761