TM 5-2420-230-24-2

Piston Rings (001-047)

B3.9 and B5.9 Series Engines

Page 1-86

Section 1 - Cylinder Block - Group 01

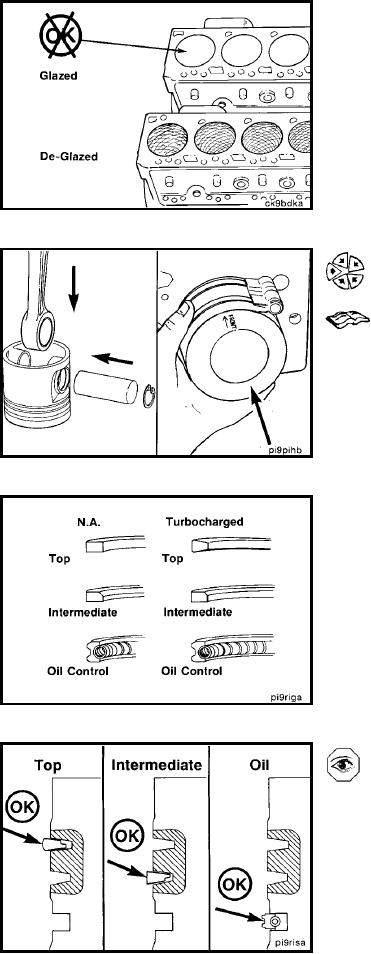

During repair it is essential that the cylinder wall be deglazed

so that new rings will seat against the cylinder wall. Failure

of the rings to seat can result in high blowby and excessive

oil consumption.

Install (001-043-026)

The piston and connecting rod must be installed as an

assembly. Refer to Procedure 001-054.

Piston Rings (001-047)

General Information

The piston ring sets are also different. While both sets

consist of three rings, the top ring of the turbocharged/

aftercooled set has a keystone profile that operates in a

ni-resist insert cast into the piston. The naturally aspirated

top ring is square cut and operates in a groove machined

into the aluminum piston.

NOTE: The top ring for a turbocharged engine is not the

same as the top ring for a naturally aspirated engine.

Inspect for Reuse (001-047-007)

Check the cylinder liners for wear. For those cylinders with

no obvious damage, check the following conditions that

can cause loss of sealing:

1. Piston rings installed incorrectly

2. Worn or damaged piston rings.

NOTE: There are two different designs of intermediate

piston rings used:

Rectangular

Reverse Twist

L-764