TM 5-2420-230-24-2

Cylinder Head (002-004)

B3.9 and B5.9 Series Engines

Page 2-10

Section 2 - Cylinder Head - Group 02

Use a straightedge and a feeler gauge to inspect the cyl-

inder head combustion surface for flatness.

Cylinder Head Flatness (6B engine)

mm

in

End-to-End

0.305

MAX

0.012

Side-to-Side

0.076

MAX

0.003

Cylinder Head Flatness (4B engine)

mm

in

End-to-End

0.203

MAX

0.008

Side-to-Side

0.305

MAX

0.012

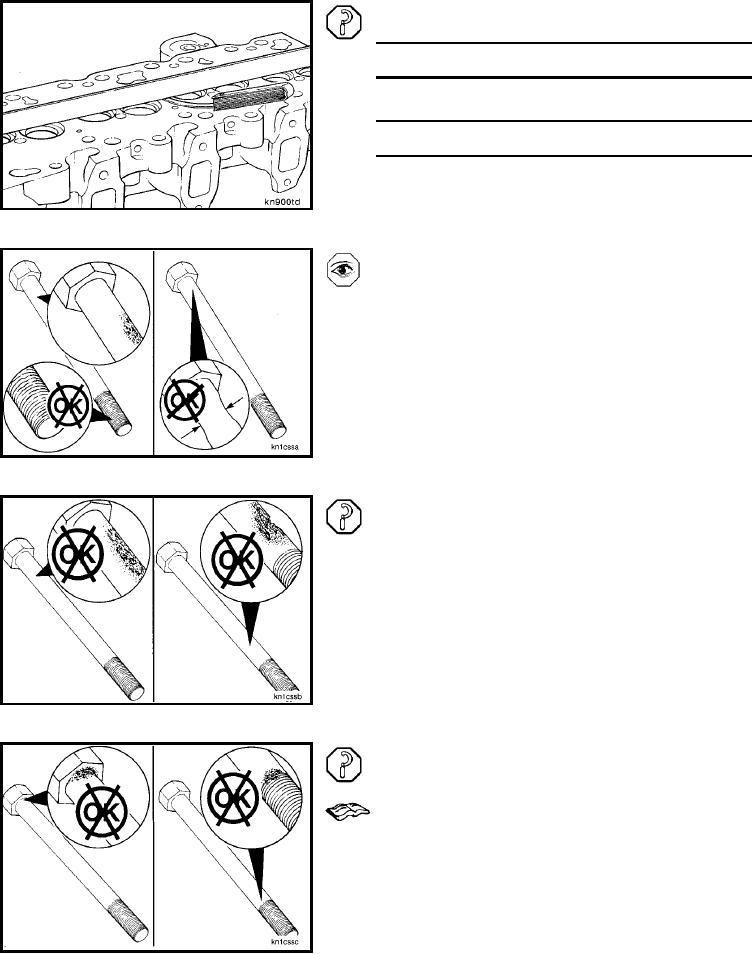

Cylinder Head Capscrews

Inspect the cylinder head capscrews for damaged threads,

corroded surfaces, or a reduced diameter (due to capscrew

stretching).

Do not reuse cylinder head capscrews under the following

conditions:

Visible corrosion or pitting exceeds 1 sq cm [0.155

sq. in] in area

Acceptable 3/8 x 3/8 inch

Unacceptable 1/2 x 1/2 inch

Visible corrosion or pitting exceeds 0.12 mm [0.005

in] in depth.

Visible corrosion or pitting is located within 3.2 mm

[1/8 in] of the fillet.

Visible corrosion or pitting is located within 3.2 mm

[1/8 in] of the threads.

Stretched beyond "free-length" maximum. Refer to

the measurement procedure below:

L-806