TM 5-2420-230-24-2

Cylinder Head (002-004)

B3.9 and B5.9 Series Engines

Page 2-14

Section 2 - Cylinder Head - Group 02

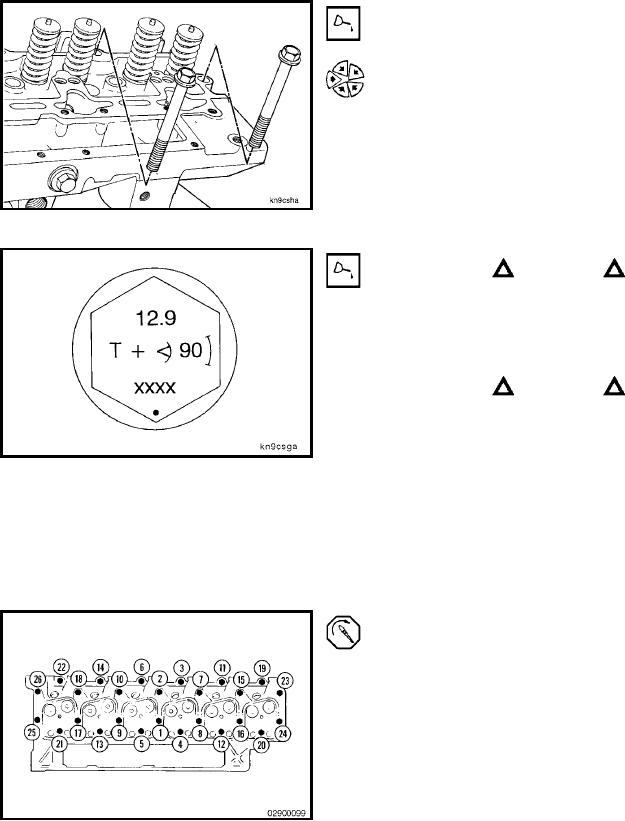

Lubricate the threads and under the heads on the remain-

ing cylinder head capscrews with clean lubricating engine

oil.

Install capscrews in the cylinder head and finger-tighten.

NOTE: Be sure to install the six capscrews into the holes

underneath the injectors.

NOTE: Capscrews for the 1991 and later certification level

engines are the same overall length, but have a longer

threaded area.

CAUTION

Do not use pre-1991 certification level engine capscrews

in a 1991 B Series or later certification level engine

because pre-1991 capscrews do not have enough

threads to provide enough thread engagement in the

1991 and later certification engines. Failure to do so can

result in engine damage.

CAUTION

Capscrews for a 1991 B Series or later certification level

engine can be used in a pre-1991 certification level

engine because 1991 and later capscrews have enough

threads to provide enough engagement in all certifica-

tion level engines.

NOTE: The top of the cylinder head capscrew is identified

with an angle marking. The cylinder head capscrews must

be tightened by using the three-step "torque plus angle"

method described as follows.

Lubricate the threads and under side of the capscrew head

of the cylinder head capscrews with clean lubricating en-

gine oil.

Step 1

1. Follow the numbered sequence, and tighten all 26

capscrews.

Torque Value: (Step 1) 90 Nm

[66 ft-lb]

L-810