TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Fuel Lift Pump (005-045)

Section 5 - Fuel System - Group 05

Page 5-85

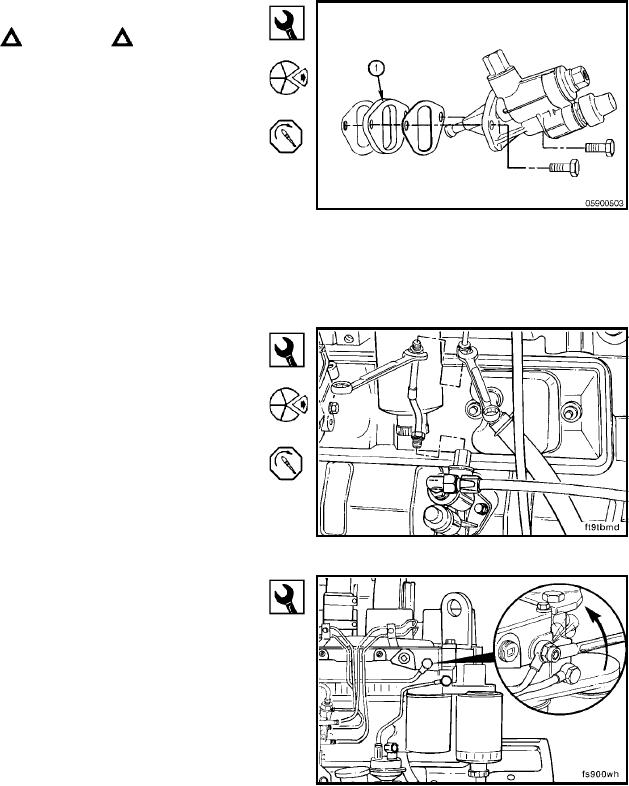

Install (005-045-026)

CAUTION

Alternately tighten the mounting capscrews. As the

capscrews are tightened, the fuel transfer pump plunger

is pushed into the pump. Failure to tighten the

capscrews in an even manner can result in the plunger

being bent or broken, causing sticking and failure.

10 mm

Diaphragm Style and Piston Style

Install the pump.

Torque Value: 24 Nm

[18 ft-lb]

The 5-mm [0.20-in] spacer (1), Cummins Part No. 3914284,

must be installed along with a gasket, Cummins Part No.

3931348, on each side of the spacer.

NOTE: For some applications, a bracket used for support-

ing other options will replace the 5-mm spacer.

14 mm, 17 mm, 20 mm

Install the fuel line to the fuel transfer pump and fuel filter

head. Use two wrenches to tighten the connection to the

pump.

Torque Value: 24 Nm

[18 ft-lb]

Vent the low-pressure fuel lines. Refer to Procedure

006-024.

Vent (005-045-032)

10 mm

Open the banjo bleed screw to bleed the low-pressure fuel

line.

L-945