TM 5-2420-230-24-2

Lubricating Oil System Diagnostics (007-048)

B3.9 and B5.9 Series Engines

Page 7-38

Section 7 - Lubricating Oil System - Group 07

CAUTION

Using a filter for a six-cylinder engine on a four-cylinder

engine does not allow extended change interval. Never

use a filter for a four-cylinder engine on a six-cylinder

engine because of the reduced material holding capa-

bility and increased chance of plugging. Failure to do

so can cause engine damage.

Lubricating Oil Filter

After the oil is cooled, it flows through the full-flow oil filter.

The filter for the six-cylinder engine is longer than the filter

for the four-cylinder engine.

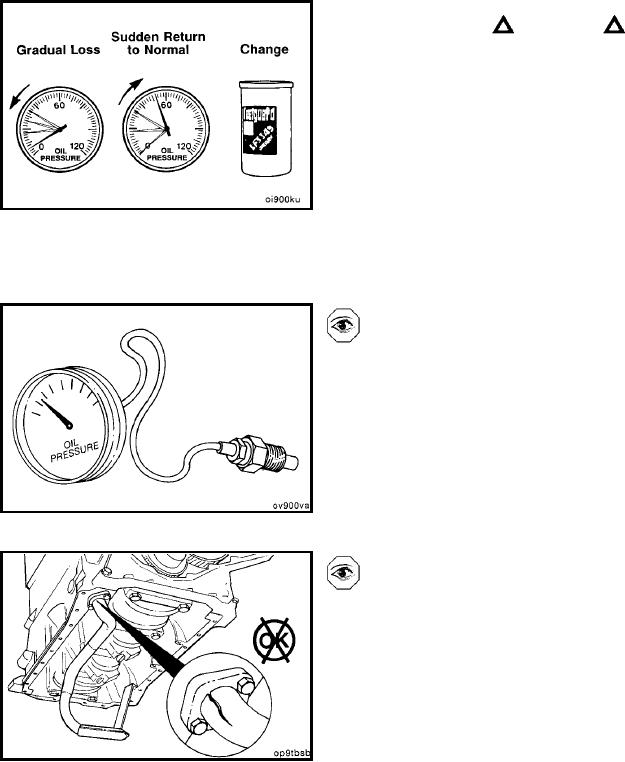

A plugged filter will cause a gradual loss of oil pressure by

approximately 69 kPa [10 psi]. The pressure will return to

normal when the filter bypass valve opens. If not corrected,

this will result in severe engine wear, as the engine is

running on unfiltered oil when the bypass valve is open.

Lubricating Oil Gauge

Check the lubricating oil gauge and sending unit to make

sure they are operating correctly by verifying the pressure

with a manual gauge connected to the main oil rifle.

Lubricating Oil Suction Tube

A loose suction tube, damaged gasket, or crack in the

suction tube can cause a temporary loss of prime for the

oil pump. The engine will have low pressure or no oil

pressure at starting, followed by normal oil pressure.

L-1050