TM 5-2420-230-24-2

Charge-Air Cooler (CAC) (010-027)

B3.9 and B5.9 Series Engines

Page 10-24

Section 10 - Air Intake System - Group 10

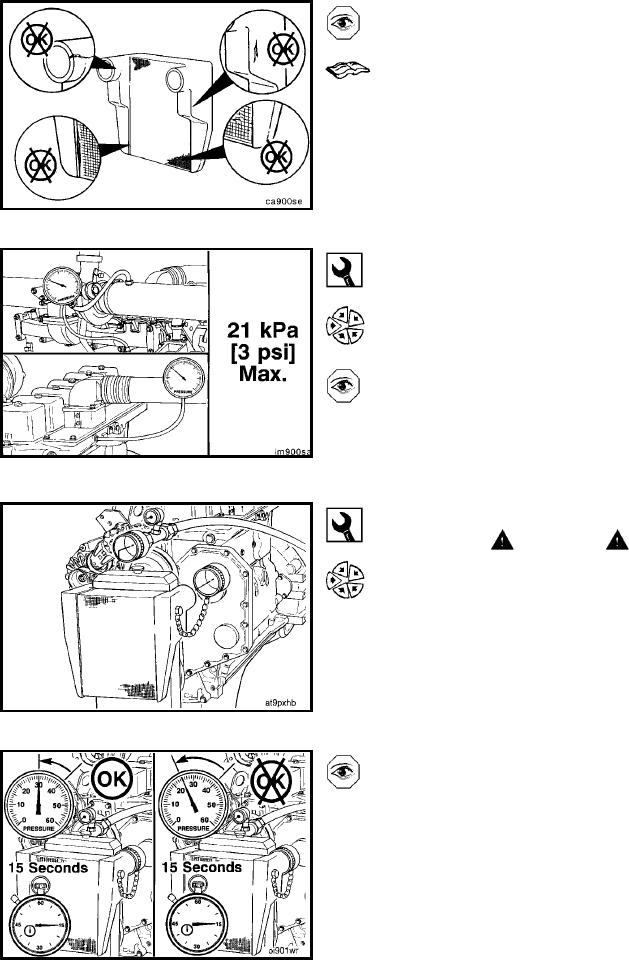

Inspect the charge air cooler for cracks, holes, or damage.

Inspect the tubes, fins, and welds for tears, breaks, or other

damage.

Refer to Section A for the leak check procedure.

Pressure Test (010-027-013)

Pressure Gauge, Part No. ST-1273

Install pressure gauge, Part No. ST-1273, to the fitting in

the turbocharger outlet.

Install another pressure gauge, Part No. ST-1273, in the

intake manifold.

Operate the engine at rated rpm and load. Record the

readings on the two gauges.

If the differential pressure is greater than 21 kPa [3 psi],

check the charge air cooler for plugging. Clean or replace

if necessary.

Differential Pressure:

21 kPa

[3 psi]

Leak Test (010-027-014)

WARNING

To avoid possible injury from either plug blowing off

during the test, secure the safety chains on the test

plugs to any convenient capscrew on the radiator as-

sembly. This test must be performed with securely fas-

tened safety chains.

Charge-Air-Cooler (CAC) Test Kit, Part No. 3824556

Install a cap over the outlet side of the charge air cooler

(CAC). Install a pressure gauge, air supply, and air pressure

regulator to the inlet side of the cooler.

Apply 207 kPa [30 psi] of air pressure to the charge air

cooler (CAC). Close the air pressure regulator.

Monitor the pressure gauge and determine the rate of

pressure decay with a stopwatch.

If the pressure decay is 49 kPa [7 psi] or less in 15 seconds,

the cooler is okay. If the pressure drop is greater than 49

kPa [7 psi] in 15 seconds, check all connections again.

Determine if the pressure decay is caused by a leak in the

charge air cooler (CAC) or from a leaky connection. Use a

spray bottle filled with soapy water applied to all hose

connections, and watch for bubbles to appear at the loca-

tion of the leak.

L-1148