TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Air Leaks, Air Intake and Exhaust Systems (010-024)

Section 10 - Air Intake System - Group 10

Page 10-21

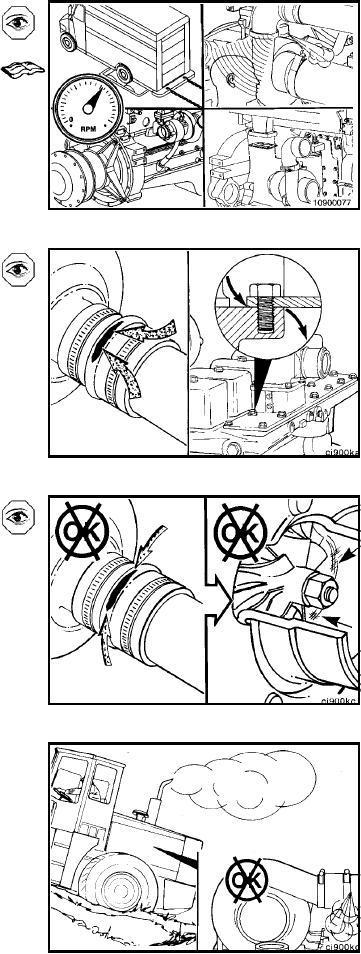

Operate the engine at full throttle and rated rpm with maxi-

mum load.

Listen again for leaks.

Replace the turbocharger if the air piping is not damaged

and the noise can still be heard. Refer to Procedure 010-033.

Damage from Nonfiltered Air

Loose connections or cracks in the suction side of the

intake pipe and after the air filter can allow debris to be

ingested by the engine, causing rapid wear in the cylinders.

Leaks at the intake manifold, unsealed bolt holes, or mani-

fold cover gasket can also allow dust and dirt to be ingested

into naturally aspirated engines.

Debris drawn into the air suction side can damage the

compressor blades, causing an imbalance resulting in bear-

ing failure.

To verify a bearing failure or damaged compressor, remove

the intake and exhaust piping, and check for contact. The

rotor assembly must rotate freely and should not be dam-

aged. Measurement of axial and radial clearance is de-

scribed in this section.

Turbocharger Engines -- Air Leaks, Pressure Side

Excessive smoke and low power from a turbocharged en-

gine can be caused by pressurized air leaking from loose

connections or cracks in the crossover tube or intake mani-

fold. This can also cause a noise problem.

L-1145