TM 5-2420-230-24-2

Air Leaks, Air Intake and Exhaust Systems (010-024)

B3.9 and B5.9 Series Engines

Page 10-20

Section 10 - Air Intake System - Group 10

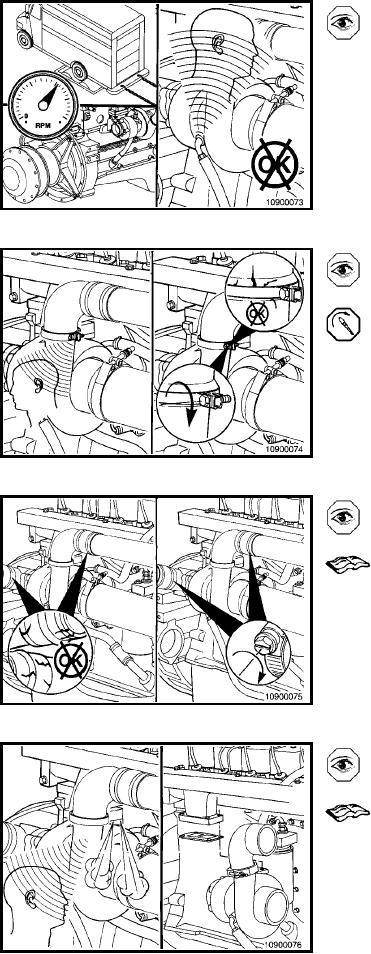

Operate the engine at full throttle and rated rpm with maxi-

mum load.

Listen for a high-pitched whistling noise from the turbo-

charger, nearby piping, and connections.

The noise can be caused by an air leak from the:

1. Turbocharger-to-discharge elbow connection.

Inspect for damage. Tighten loose clamps.

Torque Value: 8 Nm

[71 in-lb]

2. Any charge air cooler tubing or connecting hoses.

Inspect the hose and tubing for damage.

Tighten the hose clamps.

Refer to the manufacturer's specifications for the

correct torque value.

3. Turbocharger-to-exhaust-manifold mounting gasket.

Replace the gasket. Refer to Procedure 010-033.

L-1144