TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Turbocharger (010-033)

Section 10 - Air Intake System - Group 10

Page 10-31

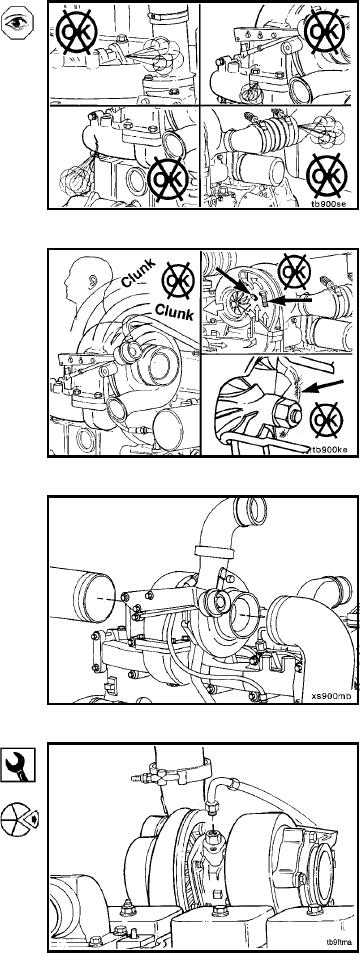

Before removing the turbocharger, make sure the noise

complaint is not caused by leaks in the air system com-

ponents.

Check for loose turbocharger mounting, exhaust manifold

gasket leaks, and cracks in the exhaust manifold.

Lower pitched sounds or rattles at slower engine speeds

can indicate that debris in the system or the rotor assembly

is touching the housings.

Remove (010-033-002)

Remove the air crossover tube, if used.

Disconnect the charge air cooler hose.

Disconnect the boost capsule actuator hose.

Disconnect and remove the exhaust and intake air piping.

16 mm and 19 mm

Remove the turbocharger lubricating oil supply line from

the turbocharger and oil filter head.

NOTE: Engines built after June 1993 can use a copper

washer in both ends of the turbocharger lubricating oil

supply line. The washer should be replaced whenever the

line is removed.

L-1155