TM 5-2420-230-24-2

Turbocharger (010-033)

B3.9 and B5.9 Series Engines

Page 10-36

Section 10 - Air Intake System - Group 10

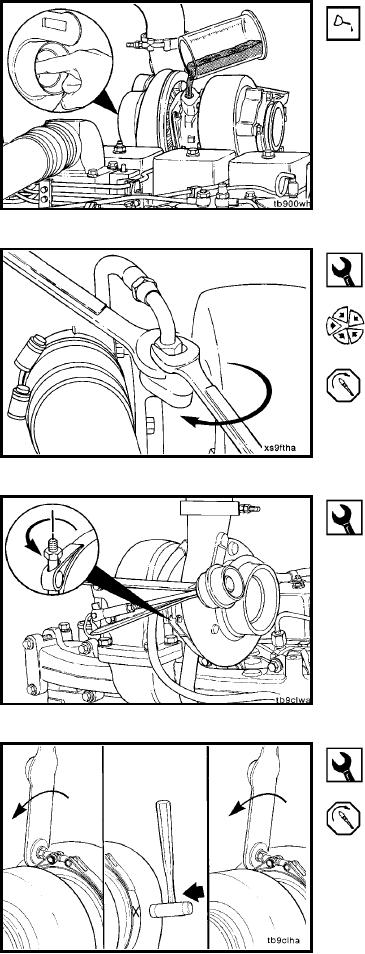

NOTE: New turbochargers must be prelubricated before

start-up.

Pour 50 to 60 cc [2 to 3 oz] of clean engine oil into the oil

supply fitting. Rotate the turbine wheel to allow the oil to

enter the bearing housing.

16 mm

Connect the oil supply line.

Torque Value: 35 Nm

[26 ft-lb]

7/16 Inch

If required, loosen the compressor housing v-band clamp

and position the housing to align with the turbocharger air

outlet tube.

If required, loosen the snap ring and align the compressor

housing with the turbocharger air outlet connection.

7/16 Inch, Plastic Hammer

Tighten the band clamp. Tap around the clamp with a

plastic hammer and tighten again.

Torque Value: 8 Nm

[71 in-lb]

NOTE: Effective October 1, 1990, all Holset Turbochargers

use silver-plated nuts with the v-band clamp. The silver-

plated nuts require a lower torque than the stainless steel

nut to provide the same v-band clamp load.

L-1160