TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Compressed Air System - General Information

Section 12 - Compressed Air System - Group 12

Page 12-3

Compressed Air System - General Information

CAUTION

Vehicles equipped with air dryers vented to atmosphere during unloaded compressor operation, using the

Holset (E-type) air compressor, require the installation of an Econ valve to prevent excessive oil consumption.

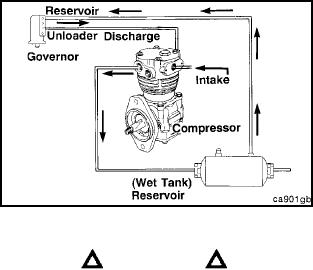

The compressed air system normally consists of a gear-driven air compressor, an air governor, air tanks, and all

necessary plumbing.

The Holset SS191B air compressor is an engine-driven, piston-type compressor that supplies compressed air to

operate air-activated devices. The compressor operates continuously but has a ``loaded'' and ``unloaded'' operating

mode. The operating mode is controlled by a pressure activated governor and the compressor unloading assembly.

When the air system reaches a predetermined pressure, the governor applies an air signal to the air compressor

unloader assembly, causing the unloader valve to hold the compressor intake valve open and compressed air to stop

flowing into the air system. As the air in the air system is used, the pressure drops. At a predetermined pressure, the

governor exhausts the air signal to the compressor unloader assembly, allowing the compressor to again pump

compressed air into the air system.

This air compressor is available in an air cooled or water cooled version, the only difference being changes to the

cylinder head to incorporate a water passage.

This air compressor is also available with or without a power steering pump housing.

Other brands of compressors can be used on the B Series engine. Troubleshooting procedures are very similar for these

air compressors compared to the Holset SS191. Refer to the specific air compressor manufacturer's manual for

detailed repair information, including torque values.

NOTE: The cylinder head and unloader components of the Holset SS191 air compressor can be serviced without

removal of the air compressor on many engine applications. This troubleshooting manual will cover servicing of the

air compressor unloader components while the compressor is still on the engine. All other servicing of the air

compressor internal components should be done after the compressor has been removed from the engine. Reference

the Shop Manual, Bulletin No. 3810433, for detailed disassembly and assembly information on air compressor SS191.

The Holset SS296 single-cylinder air compressor is an engine-driven, piston-type compressor that supplies com-

pressed air to operate air-activated devices. The compressor runs continuously but has a loaded and unloaded

operating mode. The operating mode is controlled by a pressure-activated governor and the compressor unloading

assembly.

The SS296 air compressor used on B Series engines uses an (E-type) unloader. The economy (E-type) unloader system

was designed to reduce pumping losses and engine boost pressure losses through the compressor intake valve while

operating in unloaded mode.

When the air system reaches a predetermined pressure, the governor applies an air signal to the air compressor

unloader assembly, causing the unloader cap to seal off incoming air at the intake valve and compressed air to stop

flowing into the air system.

NOTE: System pressure must be maintained on the outlet side of the discharge valve to keep the discharge valve

closed.

As the air in the air system is used, the pressure drops. At a predetermined pressure, the governor exhausts the air

signal to the compressor unloader assembly, allowing the compressor to again pump compressed air into the air system.

L-1207