TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Alternator (013-001)

Section 13 - Electrical Equipment - Group 13

Page 13-17

Measure the alternator output voltage.

System Voltage

Maximum Output Volt-

age Limit

12 VDC

15.5 VDC

24 VDC

31 VDC

Repair or replace the alternator or regulator if the voltage

limit exceeds the value in the table.

Refer to the OEM specifications for minimum voltage output.

Alternator Current Output Test

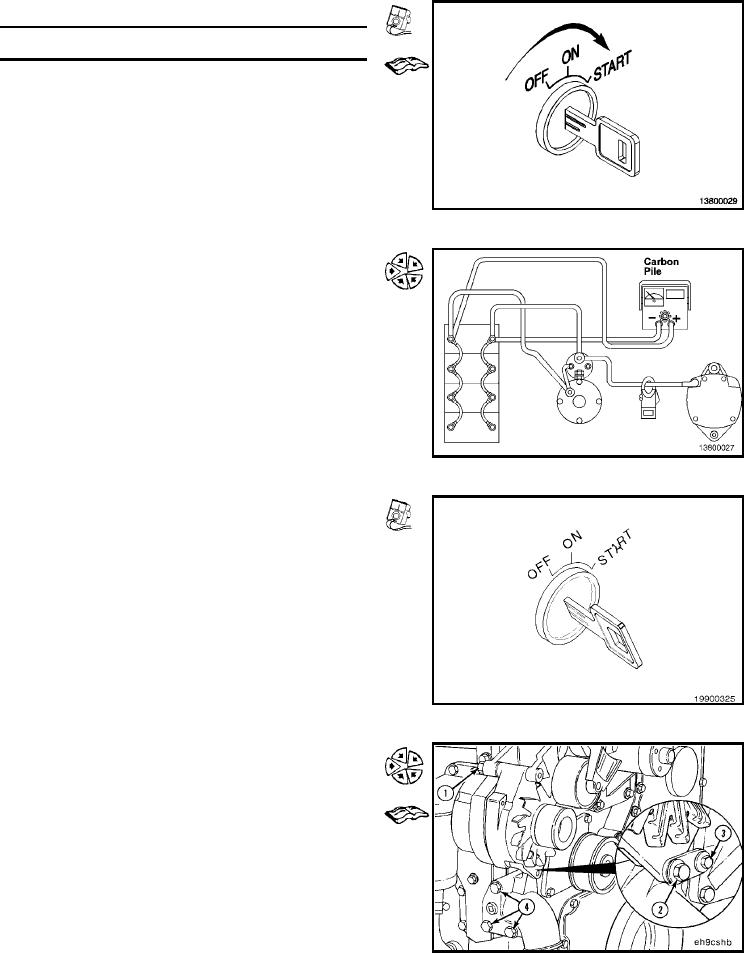

Attach the carbon pile tester and clamp-on ammeter as

shown in illustration.

Start the engine, and operate at high idle.

Adjust the carbon pile load to the rated current output of the

alternator.

If the alternator output current is not within 10 percent of

the rated output, repair or replace the alternator.

NOTE: The alternator output is directly related to the speed

the alternator is turning. A slipping alternator drive belt can

result in an incorrect output reading.

Install (013-001-026)

To assemble the alternator, the alternator mounting com-

ponents must be tightened in the following sequence:

1. Alternator-to-alternator-bracket capscrew

2. Lower brace-to-alternator capscrew

3. Lower alternator-brace-to-water-pump capscrew

4. Water-inlet-to-block capscrews.

NOTE: Wrench size and torque value are determined by

the make and model of alternator. Refer to the Engine

Component Torque Values in the specification section.

L-1275