TM 5-3805-280-10

Speed and Pressure Regulation Adjusting Instructions

36518066

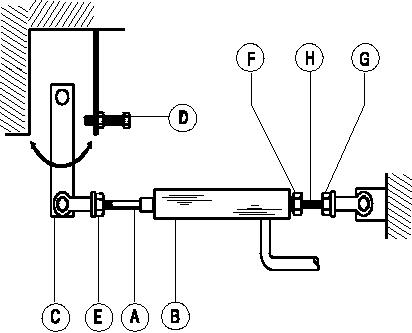

adjustment screw clockwise until throttle air (C)

Normally, regulation requires no adjusting, but if

moves against full speed governor stop (D).

proper adjustment is lost, proceed as follows:

Note: Refer to general data for machine rated

speeds and pressure.

4. Insure that pressure is maintained at rated

pressure, then turn regulator adjustment screw

Before Starting Unit:

counterclockwise until throttle arm (C) just begins

to move.

1. Atop separator tank cover at pressure valve,

loosen locknut counterclockwise. Turn adjustment

Note: Turning regulator adjustment

screw

screw and locknut counterclockwise until no

clockwise will raise pressure at full speed.

tension is felt at the screw. turn screw clockwise

5. Close service valve (engine will slow to idle

one full revolution.

speed). Loosen jam nut (E) on rod (A). Rotate rod

(A) to adjust speed to obtain idle rpm.

After Starting Unit:

6. If necessary, repeat steps 3 and 4.

2. Allow unit to warm up. Then at control panel,

7. At pressure regulator, tighten lock nut.

push "Service Air" Button, if equipped.

8. Limit full load engine speed by loosening jam

nut (F) and (G) and rotating rod (H). When proper

3. Open and adjust service valve (on outside of the

speed is reached, tighten jam nuts.

unit) to obtain the rated operating pressure on the

9. To obtain maximum CFM at any pressure

discharge pressure gauge.

between 80 PSI (550kPa) and the rated operating

pressure, turn adjustment screw of pressure

Note: If the rated operating pressure cannot be

regulator to obtain desired discharge pressure at

full load engine speed. Always lock pressure

maintained with engine at full load speed and rod

setting of adjusting screw.

(A) of air cylinder (B) fully retracted, turn regulator

7-33