TM 5-3805-280-10

Maintenance

intervals

WHEN REQUIRED

A

C

B

60 mm

Drifter chain tension

Hose tension

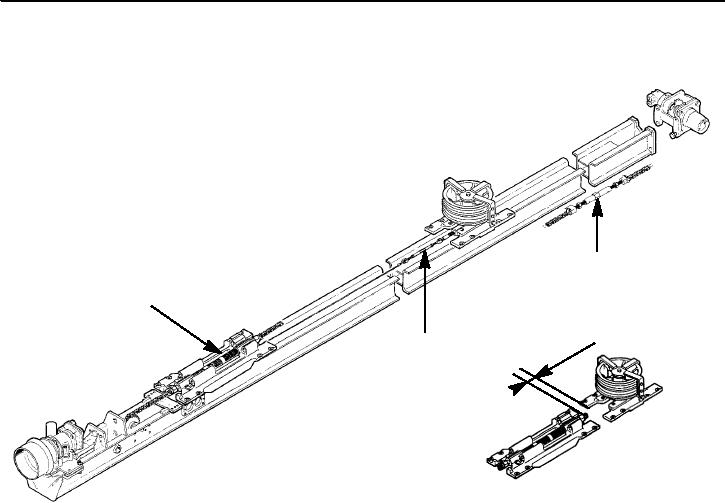

The adjustment is carried out on the chain tighten-

All the hoses should be tightened with the excep-

er A (see Figure). Generally speaking, the chains

tion of the drifter hoses (P1 and P2) which should sag

should not be too tight (the front chain vibrates abnor-

slightly when they are not under pressure (the pres-

mally during drilling) or too loose (the front chain

sure tightens these hoses when in operation).

lashes out against the feed box or the tightener

strikes against the feed extension cylinder attach-

Chain replacement

ment).

The guide should be put in toe hole drilling posi-

Change the chains when the tightener no lon-

tion, horizontal, to prevent cradles from sliding when

ger reaches their extension.

the chains or the reel rope are dismounted.

Hose reel chain tension

After chain (rope) replacement, move the drifter

back to its rear end position. Verify the distance be-

In the same way, the adjustment is carried out on

tween the drifter cradle and the hose reel cradle is 60

the chain tightener B (see Figure). The cable should

15 mm (2.4 .6 in) (see Figure).

not sag.

19-3