TM 5-3805-280-10

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 230LCR/230LCRD

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

1

Before

Check Fuel Tank (Fill at End of Day)

NOTE: Items 2 through 4 are applicable to

Model 230LCR only.

2

Before

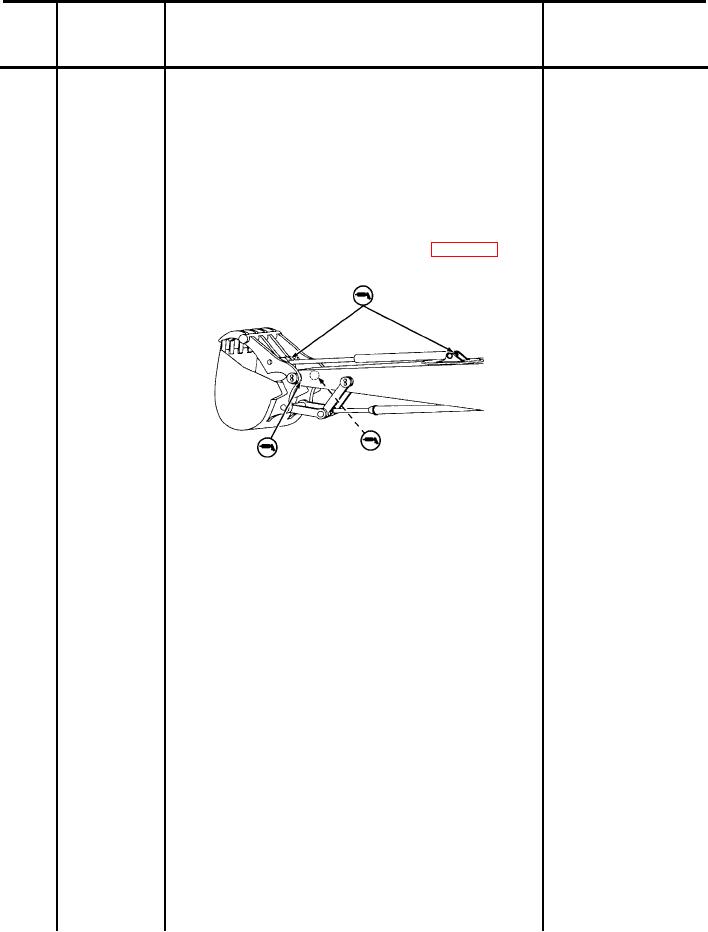

Grease All Material Clamp Joints

(1) Pump grease into the four indicated grease

Fittings damaged or

points (see Fuels and Lubricants, Chapter 9).

missing

3

Before

Check for Loose or Missing Material Clamp Bolts and Nuts

Any damage that will

prevent operation

4

Before

Inspect Material Clamp for Damage or Weld Cracks

Damage or weld

cracks are present

5

Before

Clean Dirt and Debris from Quick-Disconnect Hitch

Attachment Front Hooks and Rear Saddles

6

Before

Inspect for Damage and Clean Dirt and Debris from

Damaged sensor

Overload Alarm Proximity Sensor

NOTE: Items 7 through 16 are applicable to

Model 230LCRD only.

7

Before

Check CPA Attachment of Rock Drill to Hitch Adapter

Fixing pins are loose

or missing

(1) Ensure that all fixing pins are secure.

8

Before

Inspect Guide Chains and Ropes of the Rock Drill

2 broken wires within 36 mm

(1.44 in.) (6 times nominal

(1) Inspect the front chain for wear.

diameter of cable)

(2) Inspect hose reel rope. Specifically inspect

OR

attachment points on tightener and chain.

A-4