TM 5-3805-280-10

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 230LCR/230LCRD

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

21

Before

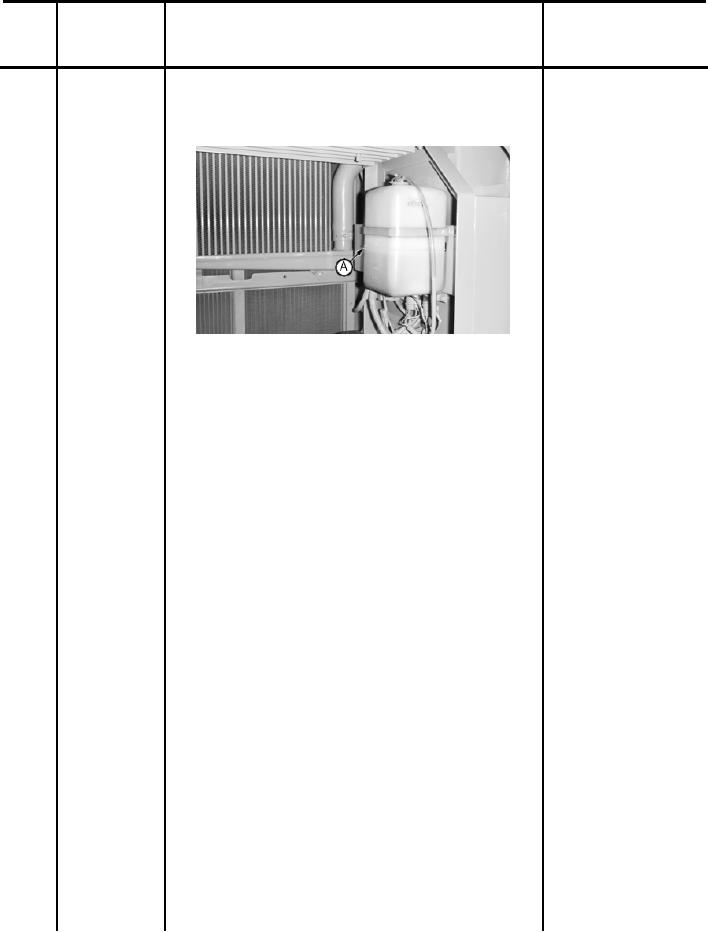

Check Recovery Tank Coolant Level

NOTE: On Model 230LCRD, the overflow

lines for the main engine and compressor

engine radiators are connected to a common

recovery tank.

(1) Open left rear access door.

(2) With engine cold, coolant level must be at the

FULL mark on the recovery tank (A).

(3) If coolant is below the FULL mark, add coolant

to the recovery tank.

WARNING: Prevent possible injury from hot

spraying water. DO NOT remove radiator

filler cap unless engine is cool. Then turn cap

slowly to the stop. Release all pressure before

you remove cap.

NOTE: If recovery tank is empty, check for

leaks. Repair as required. Add coolant to the

radiator(s) and the recovery tank.

Coolant does not cover

NOTE: Coolant level in radiator(s) must be at

cooling tubes in top of

bottom of the filler neck.

radiator

NOTE: If recovery tank is full and radiator(s)

is low, check for leaks in radiator cap and the

connections between radiator and recovery

tank.

A-9