TM 5-3805-280-24-1

Sub-System Diagnostics

NOTE: A diode can fail in two modes, either shorted or open. Continuity will be

FUEL SHUT-OFF

YES: If continuity is

measured in one direction only in a serviceable diode. Use "diode checking mode" on

SOLENOID HOLD-IN

measured in both checks,

meter when checking continuity.

COIL SUPPRESSION

diode has failed in a

DIODE (V8) AND FUEL

shorted mode. Replace.

SHUT-OFF SOLENOID

PULL-IN COIL

NO: If continuity is NOT

SUPPRESSION DIODE

measured in either check,

(V10) CHECK

diode has failed in an

open mode. Replace.

NO: If continuity is

measured in one check

and not the other, diode

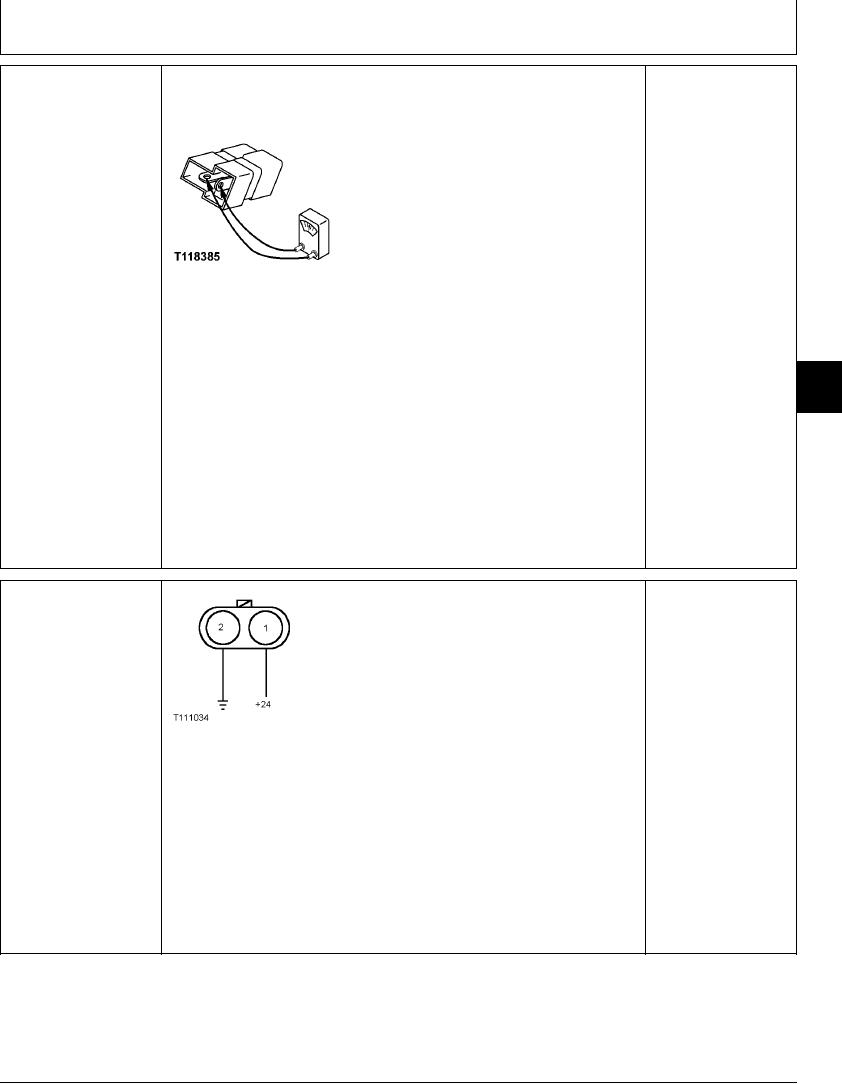

T118385 UN21NOV98

is OK.

Remove diode from connector.

Connect an ohmmeter to diode terminals.

Is continuity measured?

9015

15

Reverse ohmmeter probes.

21

Is continuity measured?

1/1

YES: Solenoid is OK. Go

START-AID SOLENOID

IMPORTANT: DO NOT start engine with start aid can

to next check.

(Y4) CHECK

removed from solenoid. Dust can enter the engine,

seriously damaging the engine.

NO: Solenoid has failed.

Replace.

Disconnect harness from start-aid solenoid.

Remove ether can from start-aid

Connect 24 volts to solenoid terminal No. 1 and ground

T111034 UN21AUG97

terminal No. 2.

Does solenoid click?

Reconnect harness.

Replace ether can.

1/1

4-86