TM 5-3805-280-24-1

Tests

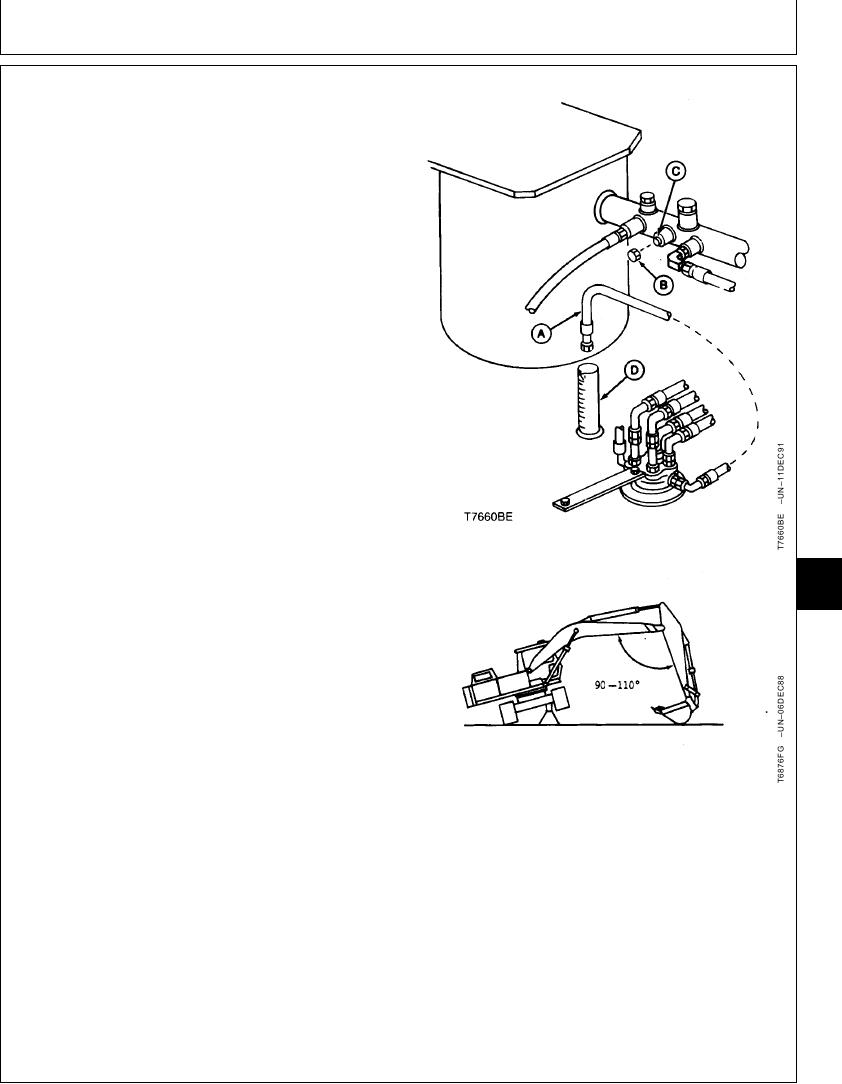

5. Disconnect the drain line (A) at return manifold. Put

line in a calibrated container (D). Install a cap (B) on

the open fitting (C).

6. Raise track off the ground for side being checked.

7. Run machine at specifications.

Engine in Standard Mode--Specification

Speed ........................................................................................... Fast Idle

Work Mode Selector--Specification

Position ........................................................................................ Dig Mode

E Mode Switch--Specification

Position .................................................................................................. Off

HP Mode Switch--Specification

Position .................................................................................................. Off

Auto-Idle Switch--Specification

Position .................................................................................................. Off

Propel Speed Switch--Specification

9025

Position ....................................................................... Slow Speed (Turtle)

25

135

8. For propel motor being checked, actuate propel

forward function at full speed for one minute. Record

amount of leakage. Repeat procedure for reverse.

If leakage is more than specification, repair or replace

motor.

Propel Motor--Specification

Leakage ................................................... 1.5--2.0 L/min (0.4--0.53 gpm)

new acceptable while propelling

with track raised

Leakage ........................................................... 3.4 L/min (0.80 gpm) used

A--Propel Motor Drain Line

maximum acceptable while

B--Cap

propelling with track raised

C--Fitting

D--Calibrated Container

If leakage is substantially more in one direction than the

other, a seal in the rotary manifold may be leaking. To

isolate leakage to the propel motor or rotary manifold,

check leakage at the propel motor.

Continued on next page

TX,9025,GG2667 1909MAY973/5

6-266