TM 5-3805-280-24-1

Tests

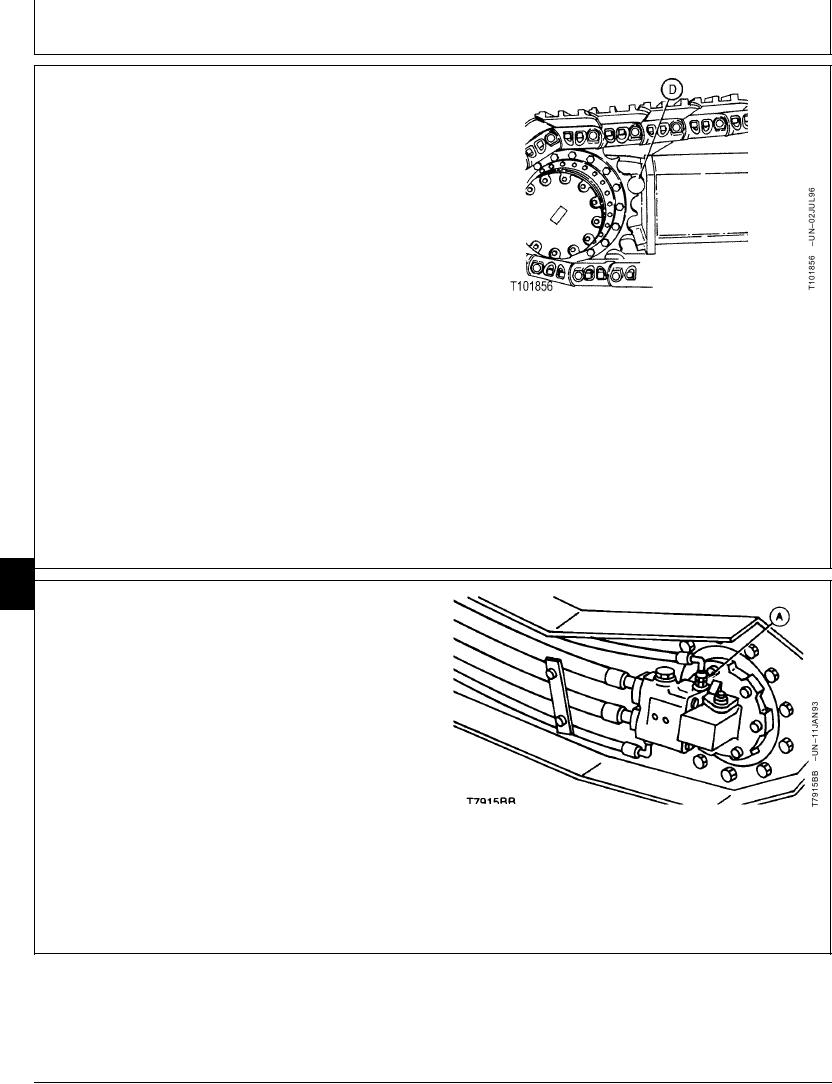

9. To check propel motor for leakage at stall, install pins

or round bar stock (D) between the sprockets and track

frame.

Propel Motor--Specification

Leakage ................................................. 1.5--4.8 L/min (0.40--1.20 gpm)

new acceptable while stalled

Leakage ........................................................... 5.2 L/min (1.40 gpm) used

maximum acceptable while

stalled

Actuate propel pedal for function being checked to full

stroke for one minute. Record the amount of

A--Pin or Round Bar Stock

leakage.Repeat procedure by stalling the motor in several

positions and then take an average of readings.

Repeat procedure for the opposite direction.

TX,9025,GG2667

1909MAY974/5

9025

25

136

10. To check leakage at the propel motor, disconnect

drain line (A) at propel motor. Install JT03221 Plug in

the line. Connect a line to fitting on motor. Put line in

a calibrated container.

Repeat Steps 7 and 8. If leakage is more than

specification, repair or replace motor. If leakage is

within specification, repair or replace rotary manifold.

A--Propel Motor Drain Line

TX,9025,GG2667

1909MAY975/5

6-267