TM 5-3805-280-24-2

Lubrication System

20

INSPECT OIL COOLER ASSEMBLY:

11

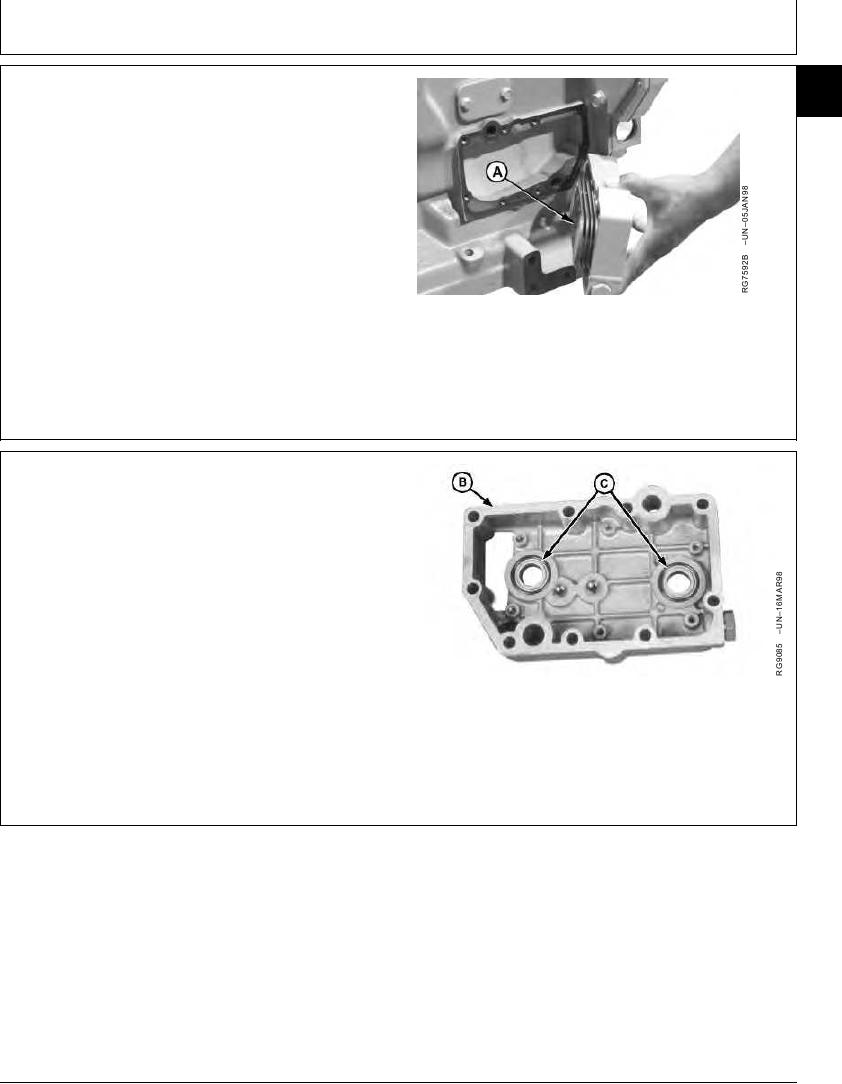

1. Inspect oil cooler (A) (shown installed in housing) for

physical damage, plugging, or leakage which may

allow mixing of oil and coolant.

2. Back flush oil cooler to clean all debris from core.

3. Pressure test oil cooler in liquid and compressed air if

mixing of oil and coolant is suspected.

Oil cooler should show no leakage when 140--170

kPa (1.4--1.7 bar) (20--25 psi) air pressure is applied

A--Oil Cooler

for a minimum of 30 seconds.

RG,20,DT7531 1917NOV972/5

4. Inspect oil cooler housing (B).

5. Replace parts as needed. DO NOT attempt to repair oil

cooler.

6. Replace O-rings (C).

B--Oil Cooler Housing

C--O-Rings

Continued on next page

RG,20,DT7531 1917NOV973/5

13-304