TM 5-3805-280-24-2

Fuel System Operation and Tests

FUEL SUPPLY QUALITY CHECK

115

32

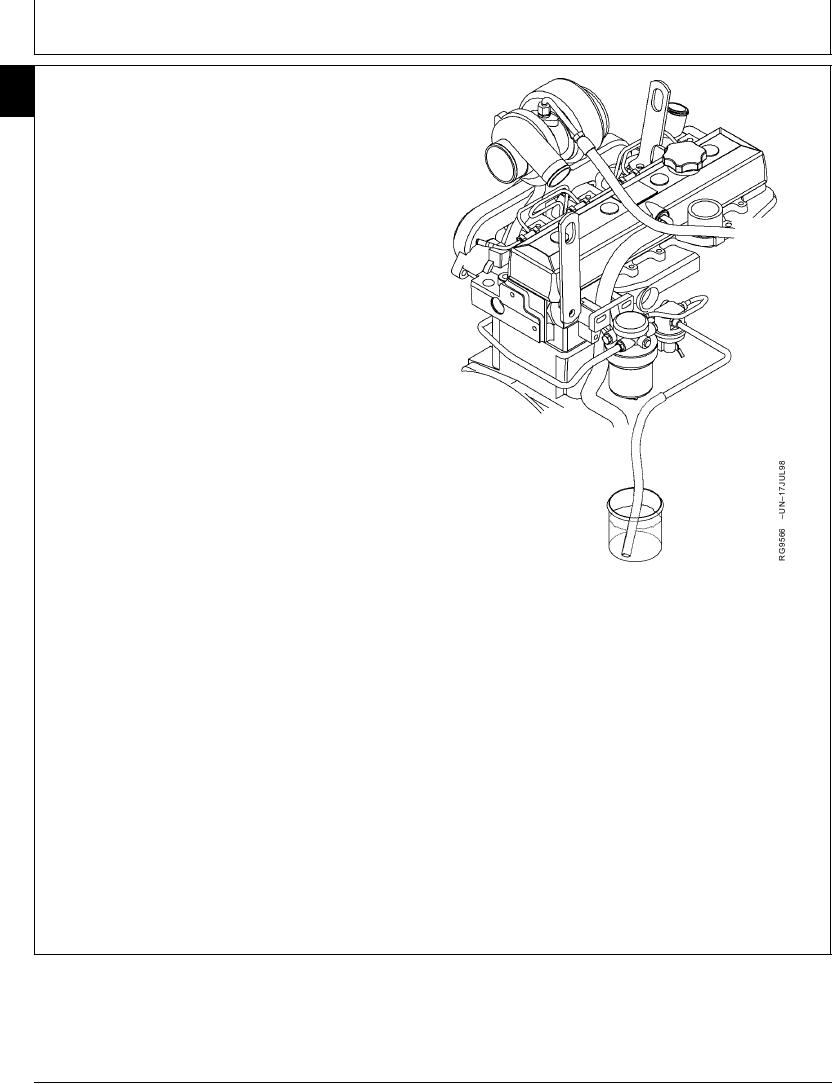

NOTE: Illustration shows fuel supply pump on engines

with rotary injection pumps. On engines with

in-line injection pumps, the supply pump is

mounted on the side of the injection pump. The

following procedure is the same for both.

The quality of diesel fuel affects engine performance.

Check your operators manual for correct fuel

specifications.

Poor quality or contaminated fuel will make the engine

hard to start, misfire, run rough or produce low power.

If poor quality or contaminated fuel is suspected, perform

the following:

1. Check primary (if equipped) and final fuel filters for

servicability. If filter is equipped with with a water

separator, empty and clean separator bowl.

2. Start engine and operate under load, observing engine

performance.

3. Disconnect fuel line from inlet side of primary fuel filter

(if equipped) or inlet side of supply pump on engines

without primary filter.

4. Connect a hose to inlet port.

5. Submerge hose in a container of clean, good quality

fuel meeting engine specifications.

6. Operate engine under load and observe performance.

If performance improves, fuel is contaminated or not of

the proper grade. Check fuel source.

DPSG,OUO1004,158 1901JUL981/1

13-559