TM 5-3805-280-24-2

Fuel System Operation and Tests

AIR IN FUEL TEST

115

33

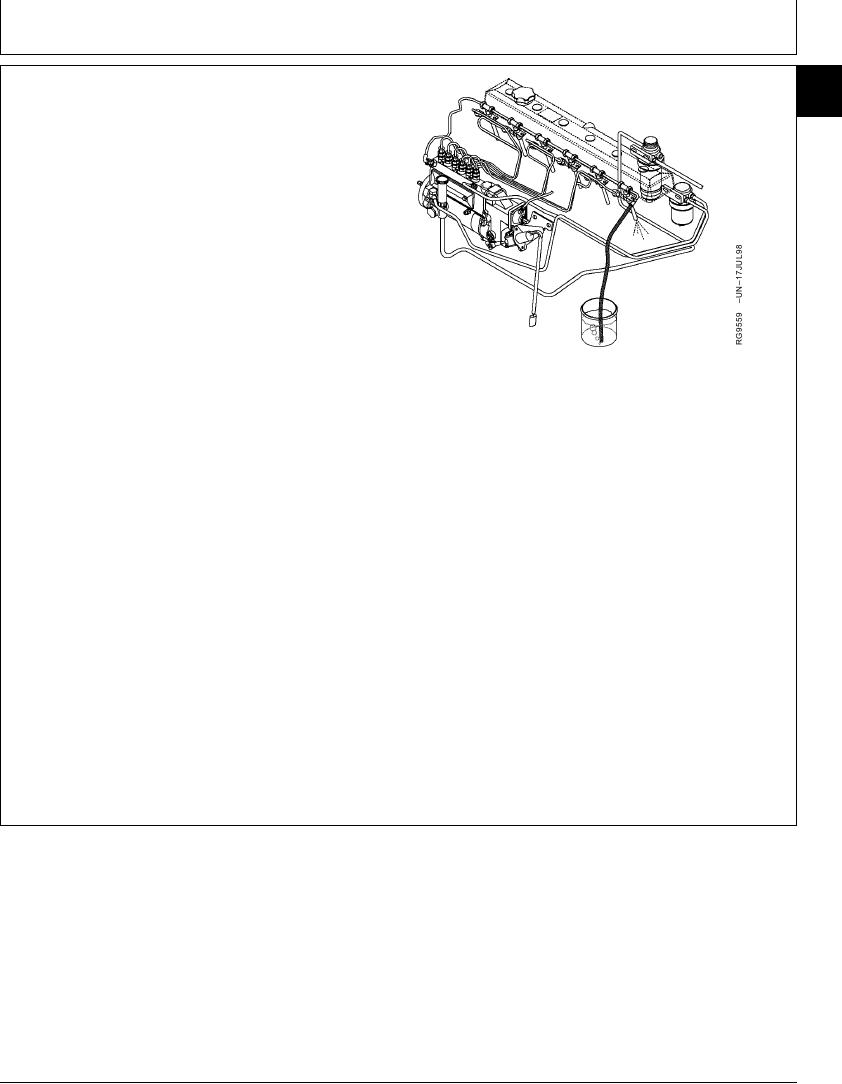

NOTE: Illustration shows in-line injection pump. Rotary

pump is similar.

Air in the fuel system will make the engine hard to start,

run rough, misfire or produce low power. Additionally, it

can cause excessive smoke and knocking.

Whenever the fuel system is opened for repair, it must be

bled to remove any air that has entered the system.

1. Disconnect hose from end of fuel leak-off line

assembly. Connect a hose to end of leak-off line

assembly and place opposite end of hose in a suitable

container filled with fuel as shown.

2. Operate engine and check for air bubbles in container.

If bubbles are present, bleed the fuel system and

repeat test. (See BLEED THE FUEL SYSTEM in this

group.)

3. If bubbles are still present, check the following:

Check for loose fuel fittings from the suction side of the

fuel supply pump to the fuel tank to inckude all lines

and filters.

Check fuel tank suction tube (if equipped) and welded

joints for cracks or holes.

Perform any necessary repairs, bleed fuel system and

repeat test.

DPSG,OUO1004,157

1901JUL981/1

13-560