TM 5-3805-280-24-2

Fuel System Operation and Tests

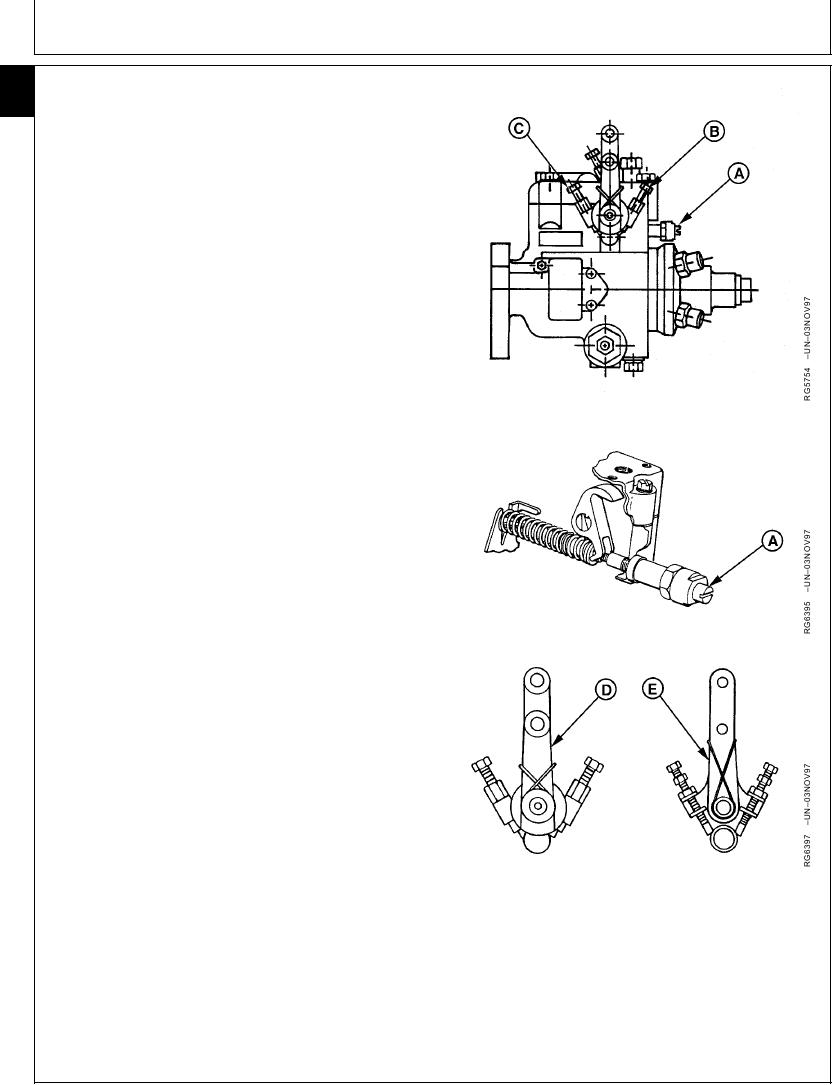

ADJUST VARIABLE SPEED (DROOP) ON

115

68

GENERATOR SET ENGINES (3--5%

GOVERNOR REGULATION)--STANADYNE

DB2 AND DB4 INJECTION PUMPS

An external speed droop adjusting cap (A) at the rear of

the injection pump housing provides precise control of

governor sensitivity by decreasing or increasing the

effective length (and thereby the rate) of the governor

control spring. Fine adjustments can be made while the

engine is operating.

1. Start engine and run at rated speed with 50% load

applied until it reaches normal operating temperature.

NOTE: If serious surging occurs during the warm-up

period, turn the speed droop adjusting cap

clockwise until surging stops.

2. When engine has warmed to normal operating

temperature, position throttle lever (D or E) to attain full

load rated speed (e.g., 1500, 1800 RPM) and apply

100% (full) load.

Adjust the throttle if necessary to obtain satisfactory full

load performance.

NOTE: Whenever speed droop adjustments are made,

throttle position adjustments will also be

necessary.

3. Remove load and check for specified no-load speed or

If incorrect, adjust speed droop adjusting cap slightly

(clockwise for increased droop or counterclockwise for

less droop).

If surging exists upon removing the load, turn the

adjusting cap clockwise to eliminate.

4. Recheck full load and no-load performance and

readjust as necessary.

A--Speed Droop Adjusting Cap

B--Fast Idle Screw

C--Slow Idle Screw

D--Early Throttle Lever

E--Current Throttle

RG,115,JW7689

1924NOV971/1

13-595