TM 5-3805-280-24-2

Fuel System Operation and Tests

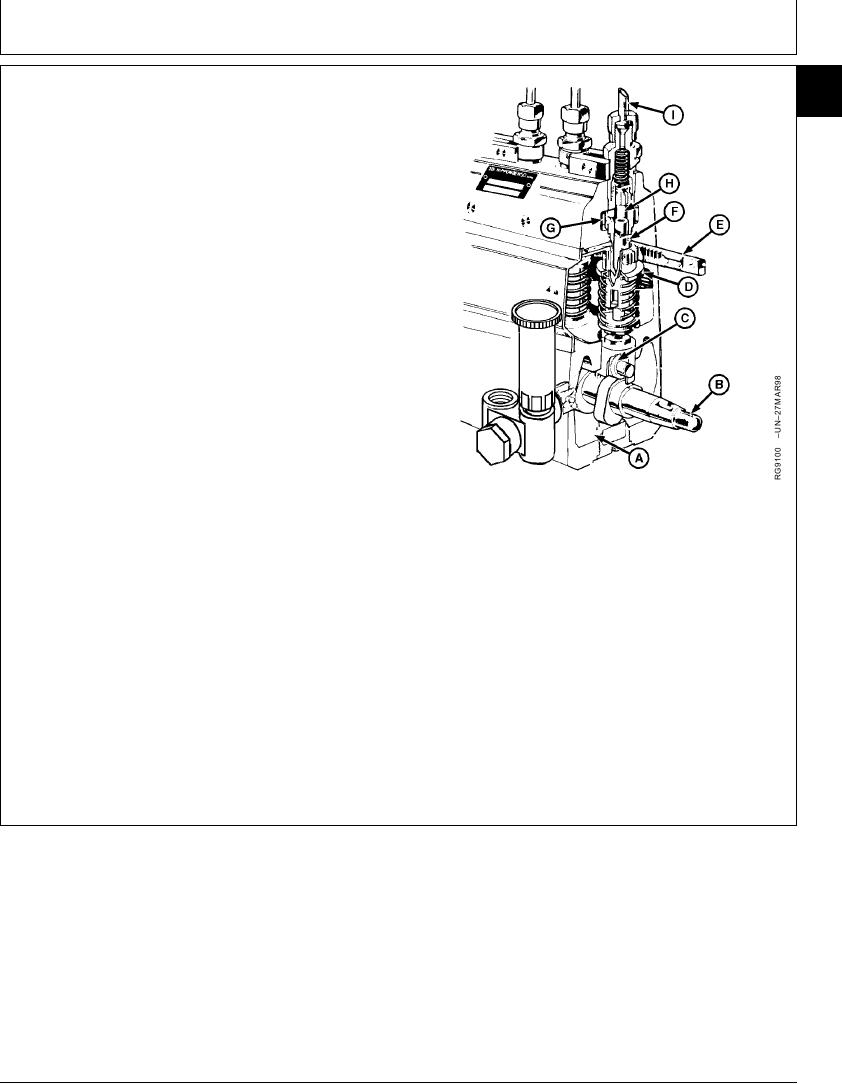

IN-LINE FUEL INJECTION PUMP OPERATION

115

69

Filtered fuel under pressure by the supply pump fills the

injection pump fuel gallery (G). As the camshaft rotates,

roller tappets (C) riding on the camshaft (B) lobes operate

the plungers (F) to supply high pressure fuel through the

delivery valves (H) to the injection nozzles.

A governor-operated control rack (E) is connected to the

control sleeves (D) and plungers to regulate the quantity

of fuel delivered to the engine.

Engine lubricating oil is piped to the injection pump

crankcase (A) to provide splash lubrication of the working

parts. Two drain holes at the front end of the pump

determine the level of oil maintained in the crankcase.

Excess oil drains out these holes and returns back to the

engine through the timing gear housing.

A--Crankcase

B--Camshaft

C--Roller Tappet

D--Control Sleeve

E--Control Rack

F--Plunger

G--Fuel Gallery

H--Delivery Valve

I--Delivery Pipe

RG,115,JW7688 1924NOV971/1

13-596