TM 5-3805-280-24-2

Fuel System Operation and Tests

CHANGE ENGINE RATED SPEED AND

115

74

ADJUST DROOP--IN-LINE INJECTION

PUMPS

1. Start engine and apply 50% load at rated speed until it

reaches operating temperature. Remove cap nuts from

adjusting screws before making adjustments.

2. When the engine has reached normal operating

temperature, adjust fast idle (stop) screw (A) clockwise

(CW) to 1500 rpm (50 Hz) with 100% (full) load.

3. Remove load and back out the idle (bumper) spring

screw (E), while observing the corresponding drop in

engine rpm's until engine quits losing speed.

4. Screw in idle (bumper) spring screw until engine speed

increases 5--10 rpm.

5. Check for specified no-load (frequency). If governor

regulation is within 5--7% range, proceed to Step 8.

NOTE: A noticeable click will occur at each 1/4 turn of

droop adjusting screw. One click CW will increase

no-load speed approximately 10 rpm,

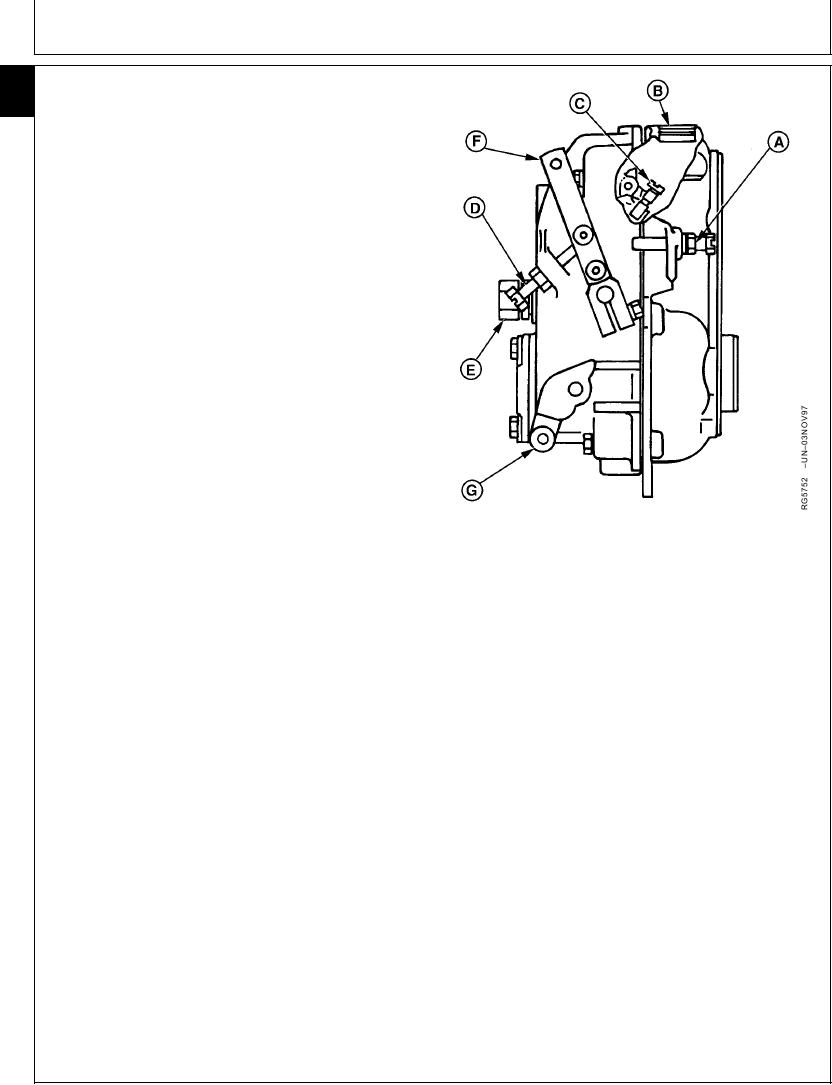

A--Fast Idle (Stop) Screw

counter-clockwise (CCW) will reduce speed by 10

B--Droop Adjusting Screw Access Plug Location

rpm.

C--Droop Adjusting Screw

D--Slow Idle (Adjusting) Screw

6. If governor regulation is above 7% or below 5%, stop

E--Idle (Bumper) Spring Screw

F--Throttle Lever

engine and remove droop adjusting screw access plug

G--Mechanical Shutoff Lever

(B, shown removed) from top of governor housing.

a. Back out slow idle (adjusting) screw (D) and

bumper screw. Pull back on throttle lever (F, toward

rear of governor housing) by hand until the droop

adjusting screw (C) inside housing can be adjusted

through the access plug hole.

b. Screw the droop screw in (CW) counting the turns

until screw bottoms out. Then, return screw to

original setting.

c. Screw in the droop screw (CW) no more than 1/2

turn (two clicks) at a time to reduce governor droop.

CCW no more than two clicks at a time to increase

governor droop (to reduce governor sensitivity).

Continued on next page

RG,115,JW7684

1924NOV971/2

13-601