TM 5-3805-280-24-2

Fuel System Operation and Tests

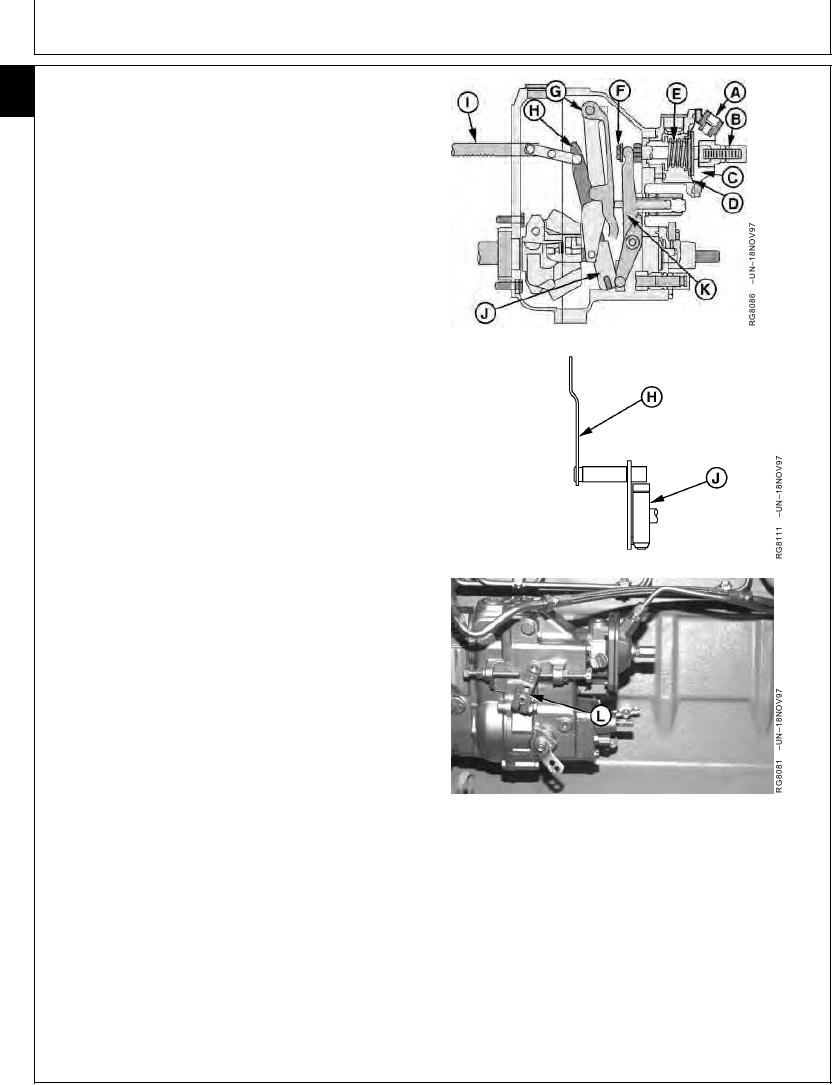

HOW THE ANEROID WORKS (IF EQUIPPED)

115

76

NOTE: In-line injection pump shown. Operation of aneroid

on rotary pumps is similar in theory.

Intake manifold pressure (created by the turbocharger)

enters aneroid at (A). It is directed to upper side of

diaphragm chamber (C) and exerts pressure on

diaphragm (D).

When the pressure rises to about 100 kPa (1 bar) (15

psi), or about 1000 engine rpm under moderate to heavy

loads, spring (E) pressure is overcome. Diaphragm then

moves aneroid control shaft (F) downward.

Control lever (H) has "two" legs. The inner leg connects

with control block (J) and the aneroid control lever (K) and

bears on the flat surface of aneroid control shaft. The

outer leg bears against a block riveted to the control rack

(I).

NOTE: Diaphragm adjusting screw (B) regulates the

minimum fuel delivery quantity at a specified rpm

and zero pressure acting on the diaphragm. The

diaphragm spring determines acceleration time

(the greater the spring tension, the greater the

manifold pressure required to overcome spring

tension; hence, a slower acceleration).

Downward movement of the throttle lever (L) causes arm

to rotate on fuel control shaft, permitting control rack to

move its normal amount.

In the intake manifold pressure is below 100 kPa (1 bar)

(15 psi) because of low engine speed, or is under light

load at higher engine speeds, the aneroid spring pressure

is greater than the intake manifold pressure. As a result,

the control rack travel is limited (therefore, fuel delivery is

limited) by the arm and adjusting shaft.

Aneroid control will be in effect until the manifold pressure

A--Intake Manifold Pressure Line Connection

is high enough to overcome diaphragm spring pressure.

B--Diaphragm Adjusting Screw

C--Diaphragm Chamber

D--Diaphragm

E--Spring

F--Aneroid Control Shaft

G--Guide Lever

H--Control Lever

I--Control Rack

J--Control Block

K--Aneroid Control Lever

L--Throttle Lever

RG,115,JW7683

1924NOV971/1

13-603