TM 5-3805-280-24-2

Fuel System Operation and Tests

FUEL INJECTION NOZZLES--GENERAL INFORMATION AND OPERATION

115

78

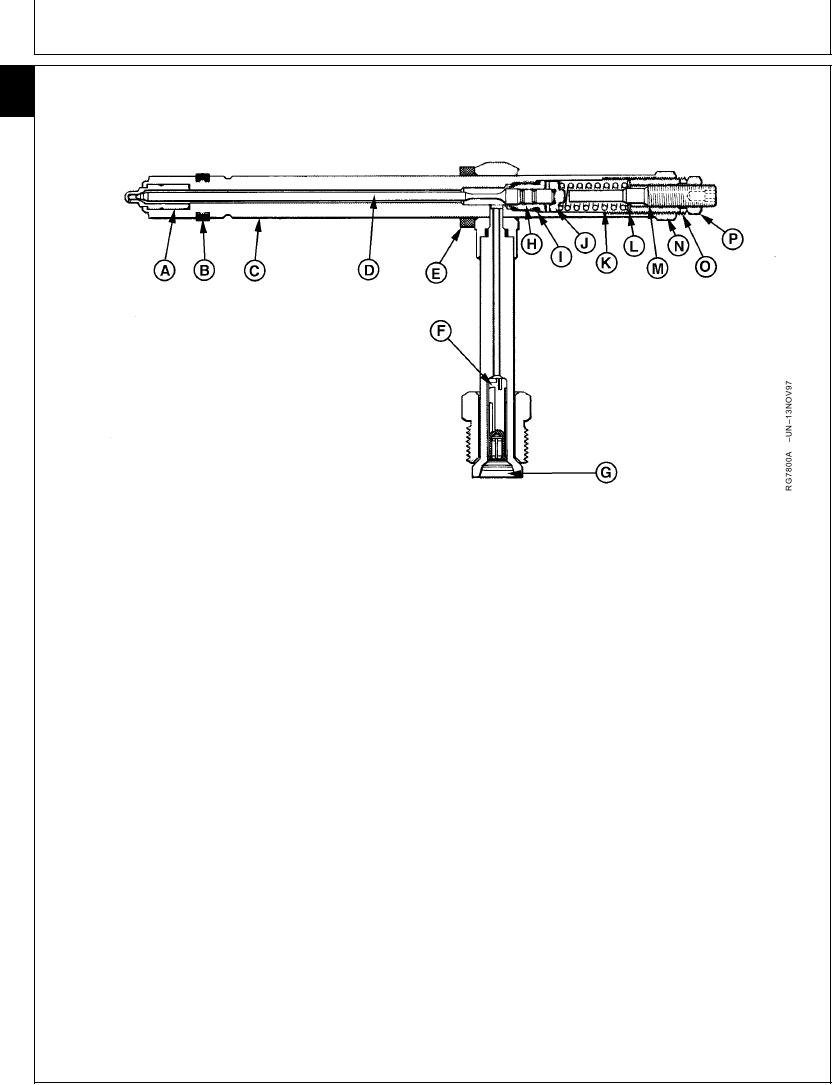

A--Nozzle Tip

F--Edge-Type Filter

K--Valve Spring

O--Pressure Adjusting

B--Carbon Stop Seal

G--Fuel Inlet

L--Spring Washer

Screw

C--Nozzle Body

H--Upper Guide

M--Lift Adjusting Screw

P--Lock Nut

D--Nozzle Valve

I--Upper Seal

N--Lock Nut

E--Upper Seal Washer

J--Spring Seat

A leak-off line tee is attached to the upper end of the

The injection nozzles are located in the engine cylinder

injection nozzle, secured by a grommet and hex nut.

head and are of the spring and valve type,

hydraulically operated by fuel delivered from the

Metered fuel, under high pressure, is delivered by the

injection pump.

injection pump through the nozzle inlet (G) on the

valve body into the area surrounding the valve. When

A locating clamp positions the nozzle assembly in the

fuel pressure reaches nozzle opening pressure, the

cylinder head. The nozzle is sealed at the top end by a

valve is forced from its seat against the pressure of the

seal washer (E). A carbon stop seal (B), located on the

spring, permitting a measured amount of fuel to enter

lower end of the nozzle body (C), prevents carbon

the combustion chamber through four small holes in

from collecting around the nozzle in the cylinder head.

the nozzle tip.

Enclosed in the nozzle body are the valve (D), valve

After fuel has been injected, the spring closes the

spring (K), and spring seat (J). The nozzle operating

valve. In actual operation, the valve opens and closes

pressure is controlled by the pressure adjusting screw

very rapidly, providing a distinct chatter.

(O) in the upper end of the nozzle body. Valve lift is

adjusted by the lift adjusting screw (M) located in the

pressure adjusting screw. The nozzle tip (A) is pressed

into the nozzle body and cannot be separated.

Continued on next page

RG,115,JW7681

1924NOV971/2

13-605