TM 5-3805-280-24-2

Mechanical Drive Elements

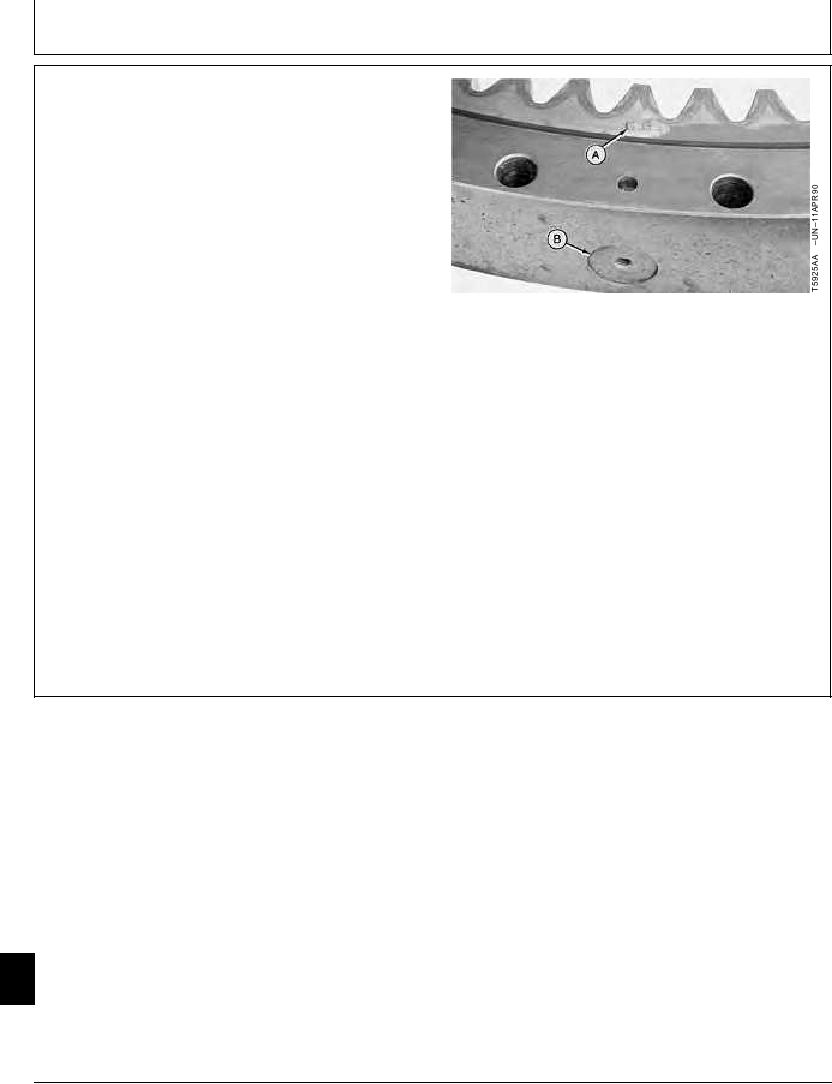

IMPORTANT: The tooth marked with the letter "G" or

"S" or equivalent is the starting and

stopping point for the hardening

process. The tooth and the bearing

loading plug must be installed on the

right side of the machine so the use of

that part of the swing bearing is

minimized.

6. Install swing bearing on undercarriage so the tooth (A)

marked "G" or "S" or equivalent and bearing loading

plug (B) is to the right side of machine.

A--Tooth

7. Install cap screws and lock washer. Tighten cap

B--Loading Plug

screws.

Undercarriage-to-Swing Bearing Cap Screw--Specification

Torque ......................................................................... 740 Nm (540 lb-ft)

8. Apply multi-purpose EP grease to swing bearing teeth

and pinion shaft. (See Track Adjuster, Working Tool

Pivot, Swing Bearing, and Swing Bearing Gear Grease

in Group 0004.)

TX,43,UU4005

1923SEP982/2

43

4350

30

22-29