TM 5-3805-281-24-1

Tests

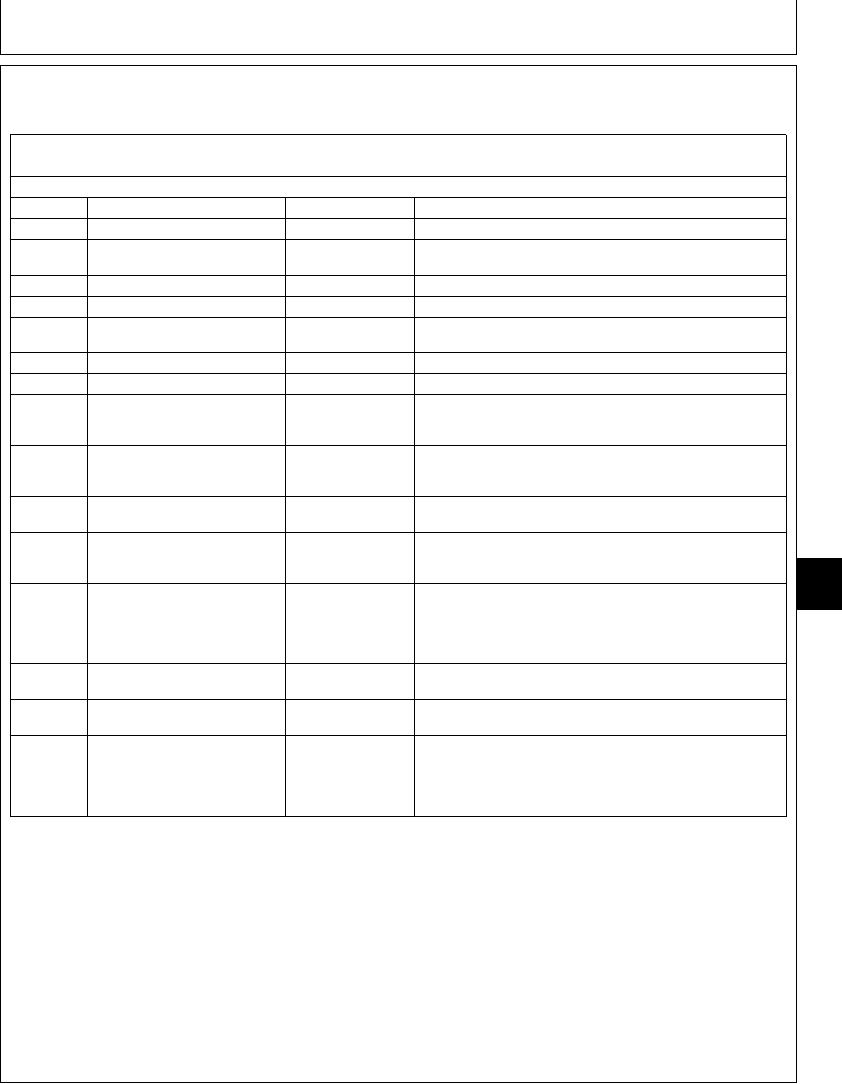

EXCAVATOR DIAGNOSTICS PROGRAM--

MONITOR DATA ITEMS

NOTE: This chart lists engine and pump controller dynamic data items that can be monitored by the excavator

diagnostics program.

330LCR MONITOR DATA ITEMS

Item

Display List

Units

Description

1

Front pump control pressure

psi

Pilot signal from the front pump control valve to pump regulator

2

EC angle

V

Feedback signal from the engine control sensor to the engine and

pump controller

3

Front pump delivery pressure

psi

Pump supply pressure at front pump outlet.

4

Rear pump delivery pressure

psi

Pump supply pressure at rear pump outlet.

5

Arm in pilot pressure

psi

Pilot pressure from pilot controller to control valve pilot cap.

Pressure measured at flow regulator valve.

6

Rear pump control pressure

psi

Pilot signal from rear pump control valve to pump regulator.

8

RPM dial angle

V

Electrical signal from engine rpm dial.

9

Arm regenerative control pressure

psi

Pilot pressure from arm regenerative solenoid valve to arm

regenerative valve in left control valve. A calculated pressure, not

actual pressure.

10

Propel motor control pressure

psi

Pilot pressure from propel speed change solenoid valve to speed

selector valve in propel motors. A calculated pressure, not actual

pressure.

11

Speed sense control pressure

psi

Pilot pressure from speed sense solenoid valve to front and rear

pump regulators. A calculated pressure, not actual pressure.

12

Power boost control pressure

psi

Pilot pressure from power boost solenoid valve to the piston in the

system relief valve. This is a calculated pressure, not the actual

9025

pressure.

25

13

Target engine speed

rpm

Set by engine rpm dial position. Used with actual engine speed

23

and pump delivery pressure signals to control the load (pulldown)

on engine by energizing speed sensing solenoid valve to reduce

pump flow. (Approximately 150 rpm less than actual engine speed

under no load.)

14

Actual engine speed

rpm

Engine speed sensed by engine speed sensor. Sensor is located

in the pump drive gearbox adjacent to front pump.

15

EC motor position

steps

Electrical signal from engine and pump controller to engine control

motor.

20

Pressure switch

Boom Up, Dig,

Electrical signal from pressure switches to engine and pump

Propel

controller when function is actuated. Boom up is located on flow

regulator valve. Dig is located at the swing park brake release

valve. Propel is located at the shuttle valve fasten to the front of

control valve mounting bracket.

Continued on next page

CED,TX08227,3018 1916MAR981/2