TM 5-3805-281-24-2

Cylinder Head and Valves

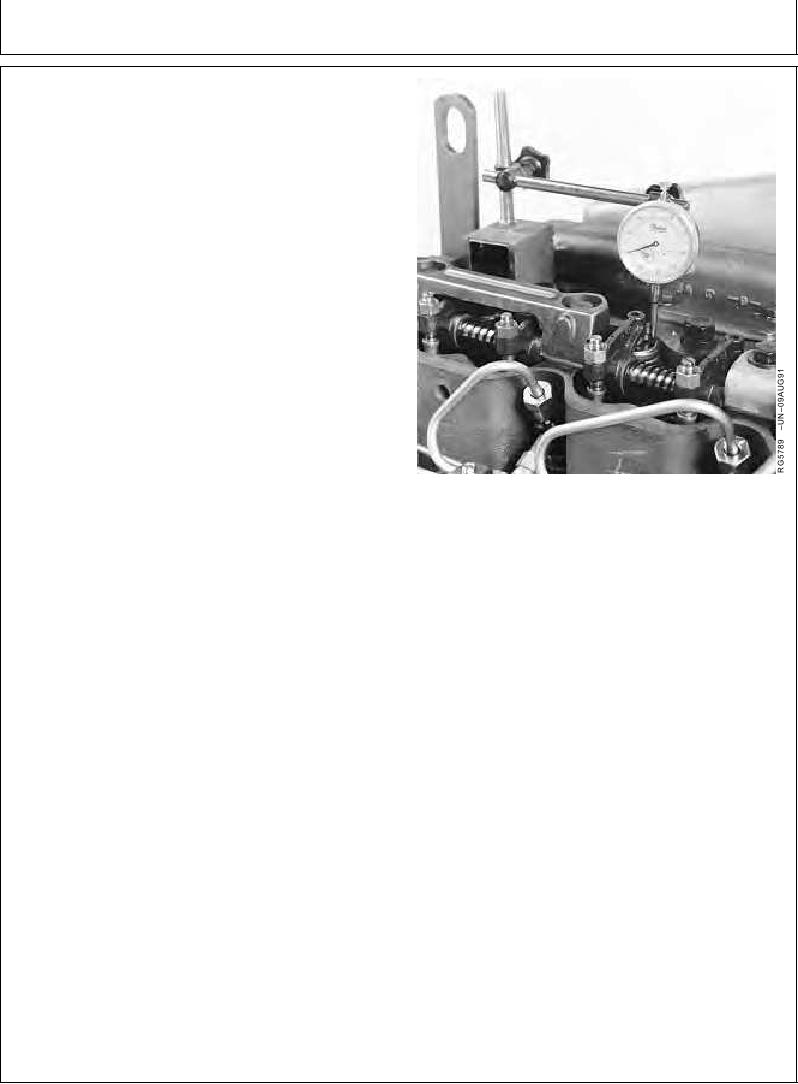

CHECK VALVE LIFT

IMPORTANT: For a more accurate measurement, it is

recommended that valve lift be

measured at 0.00 mm (in.) valve

clearance and with engine COLD.

NOTE: Measuring valve lift can give an indication of wear

on camshaft lobes and cam followers or wear on

camshaft lobes and cam followers or bent push

rods.

1. Remove turbocharger oil inlet clamp and rocker arm

cover. Loosen lock nut on rocker arm. Set valve

clearance at 0.00 mm (in.) on valve being checked.

Tighten lock nut.

2. Put dial indicator tip on valve rotator. Be sure that

valve is fully closed.

3. Check pre-set on dial indicator. Set dial indicator

pointer at zero.

Checking Valve Lift

4. Manually turn engine in running direction, using the

engine rotation tools previously mentioned for checking

valve clearance.

5. Observe dial indicator reading as valve is moved to

fully open position. Record reading and valve number.

Intake Valve--Specification

Lift .......................................................... 13.53--13.71 mm (0.533--0.540

in.) at 0.00 mm (in.) clearance

Wear Tolerance ..................................... 12.65 mm (0.498 in.) at 0.00 mm

(in.) clearance

Exhaust Valve--Specification

Lift .......................................................... 14.52--14.60 mm (0.572--0.579

in.) at 0.00 mm (in.) clearance

Wear Tolerance ..................................... 13.64 mm (0.537 in.) at 0.00 mm

(in.) clearance

6. Reset valve clearance to specification after measuring

lift. (See CHECK AND ADJUST VALVE CLEARANCE,

earlier in this group.)

7. Repeat procedure on all remaining valves.

RG,RG34710,1070

1923OCT971/1