TM 5-3805-281-24-2

Cylinder Block, Liners, Pistons, and Rods

IMPORTANT: ALWAYS measure liners at room

temperature.

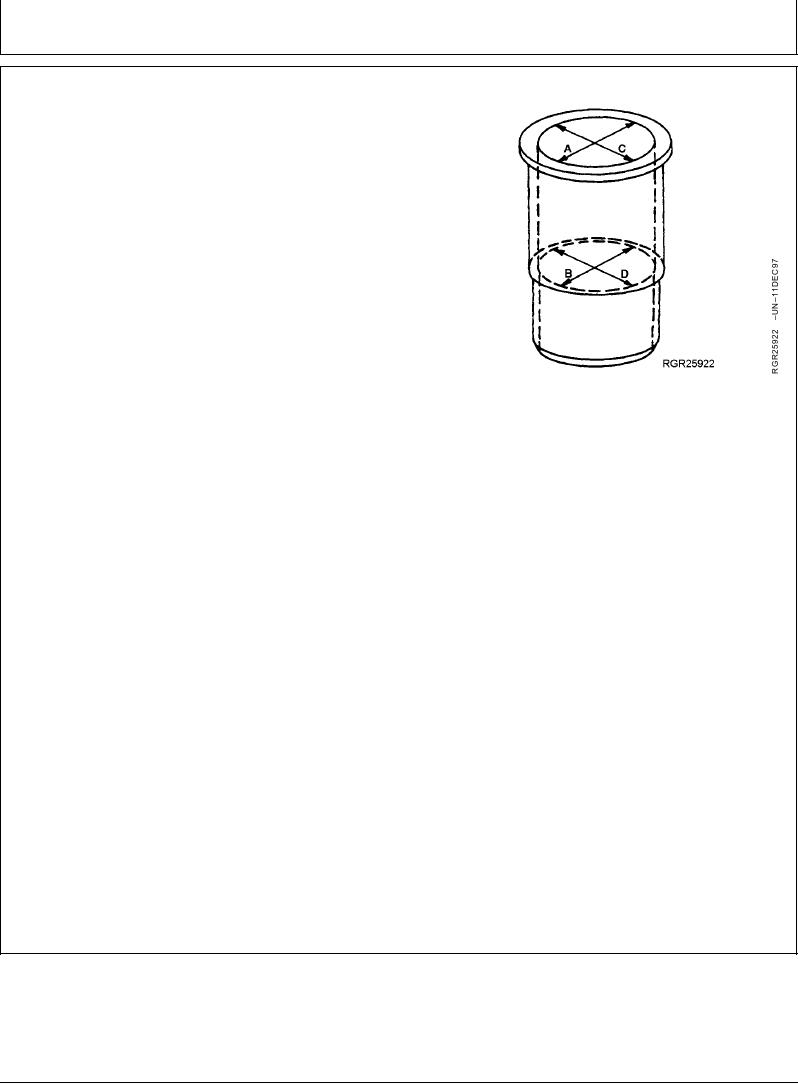

3. Measure liner bore parallel to piston pin at top end of

ring travel (A).

4. Measure bore in same position at bottom end of ring

travel (B).

5. Measure bore at right angle to piston pin at top end of

ring travel (C).

6. Measure bore in same position at bottom end of ring

travel (D).

7. Compare measurements A, B, C, and D to determine if

liner is tapered or out-of-round.

Measuring Cylinder Liners

8. Compare liner I.D. with matched piston O.D.

Cylinder Liner--Specification

ID ........................................................................... 115.865--115.895 mm

(4.5616--4.5628 in.)

Maximum Out-of-Round ......................................... 0.051 mm (0.0020 in.)

Cylinder Liner in Ring Travel Area--Specification

Wear ....................................................... 0.051 mm (0.0020 in.) maximum

Piston-to-Liner--Specification

New Part Clearance ...................................................... 0.076--0.124 mm

(0.0030--0.0049 in.)

Maximum Clearance............................................... 0.152 mm (0.0060 in.)

Replace piston and liners (as a set) if they exceed wear

specifications given.

RG,RG34710,1125

1923OCT972/2

11-165