TM 5-3805-281-24-2

Cooling System

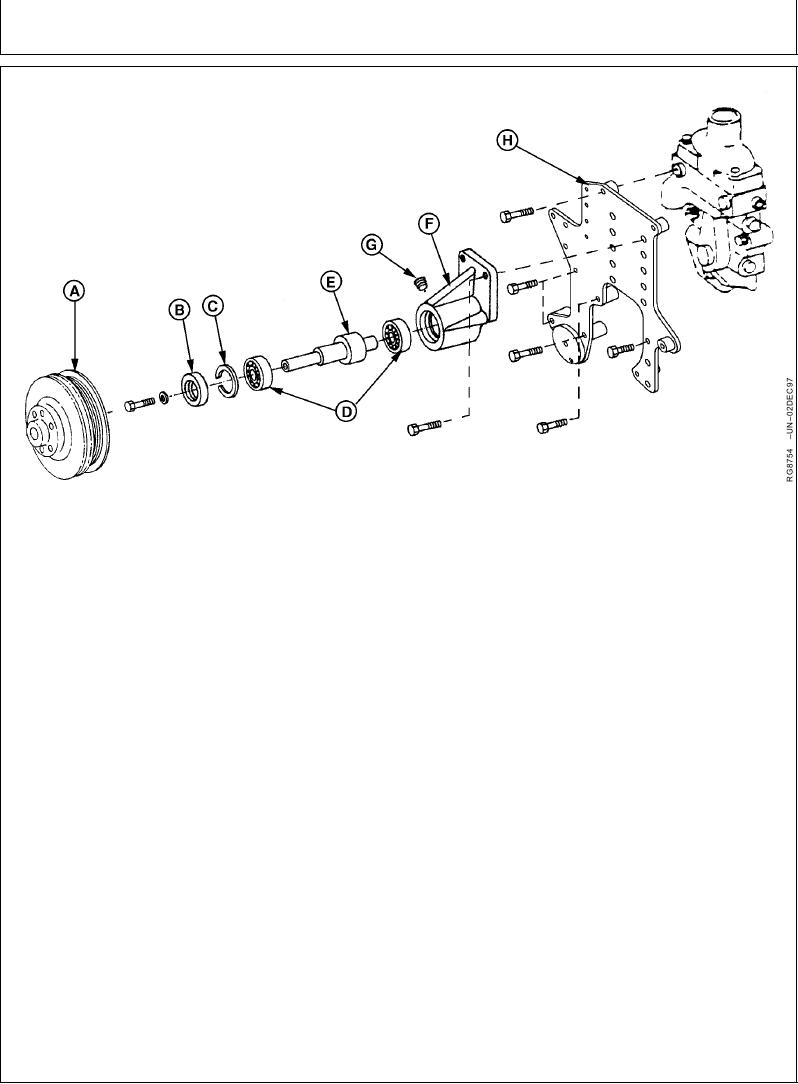

Heavy-Duty Adjustable Fan Drive Assembly

A--Fan Hub/Pulley

C--Snap Ring

E--Shaft

G--Pipe Plug

B--Grease Seal

D--Ball Bearing (2 Used)

F--Bearing Housing

H--Support Plate

6. Install snap ring in housing groove. Visually inspect

TO ASSEMBLE FAN DRIVE:

snap ring installation for proper seating in housing

groove.

1. Pack inner and outer bearings (D) with TY6333 or

TY6347 High Temperature Grease. Apply clean

7. Apply a thin coat of clean engine oil to O.D. of seal

engine oil to bearing I.D. and shaft O.D.

casing (B) and to seal lips. Install seal in housing

bore until metal casing is flush-to-0.50 mm

2. Support end of shaft (E) and install bearings

against shoulder. Apply force to bearing inner race

(0.020 in.) below housing face.

only.

8. Apply clean engine oil to I.D. of fan hub/pulley (A).

Support end of shaft through pipe plug hole in

3. Support bearing housing (F) on a firm flat surface

bearing housing and push onto other end of shaft

with bearing bore in the upward position.

until it bottoms against shoulder.

4. Install bearing and shaft assembly into housing.

9. Install washer and cap screw. Tighten cap screw to

Small end of shaft should extend through housing.

80 Nm (60 lb-ft).

5. Determine proper snap ring (C) thickness needed to

obtain 0.10 mm (0.004 in.) end play.

Continued on next page

RG,RG34710,1239

1923OCT973/4

11-306