TM 5-3805-281-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 330LCR

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

3

*As Required

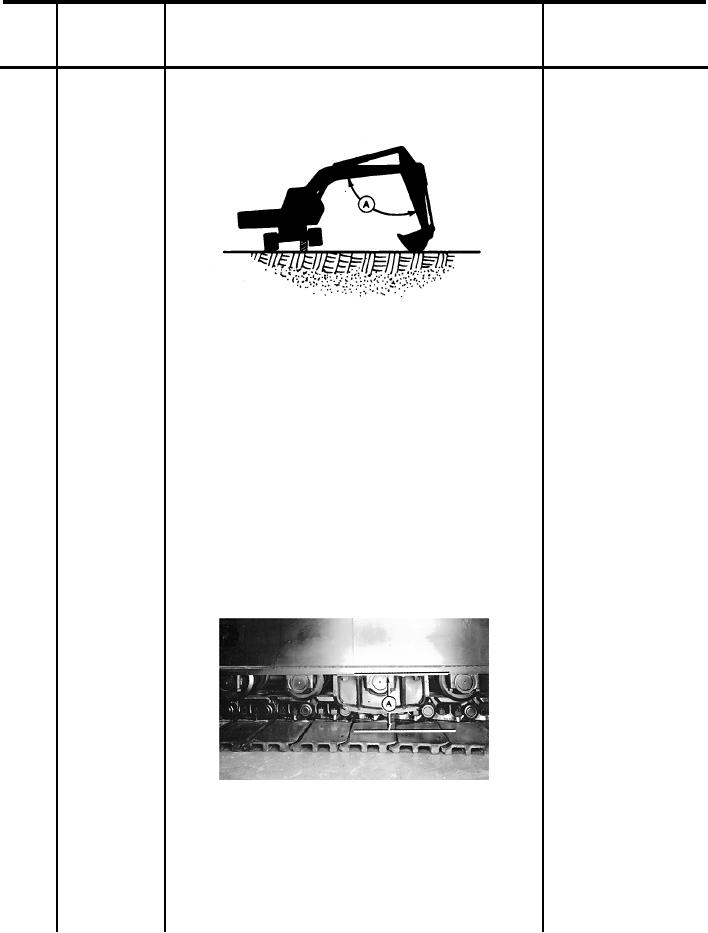

Check Track Sag

(1) Swing upperstructure 90 and lower bucket to

raise track off ground.

(2) Keep the angle (A) between 90--110 and

position bucket's round side on the ground.

CAUTION: Prevent possible injury from

unexpected machine movement. Place blocks

under frame to support machine while

measuring track sag.

(3) Place blocks under machine to support

machine.

(4) Rotate track forward two full rotations and then

in reverse two full rotations.

(5) Measure the distance (A) at middle track roller

from bottom of track frame to top surface of

track shoe.

TRACK SAG SPECIFICATIONS

Normal Ground Conditions

300--335 mm

(11-13/16--13-3/16 in.)

A-4