TM 5-3805-281-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 330LCR

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

4

*As Required

Adjust Track Sag

CAUTION: Prevent possible damage to

track components. DO NOT use the grease

fitting on the track-adjusting cylinder for

lubrication. Use this fitting ONLY for track

adjustment.

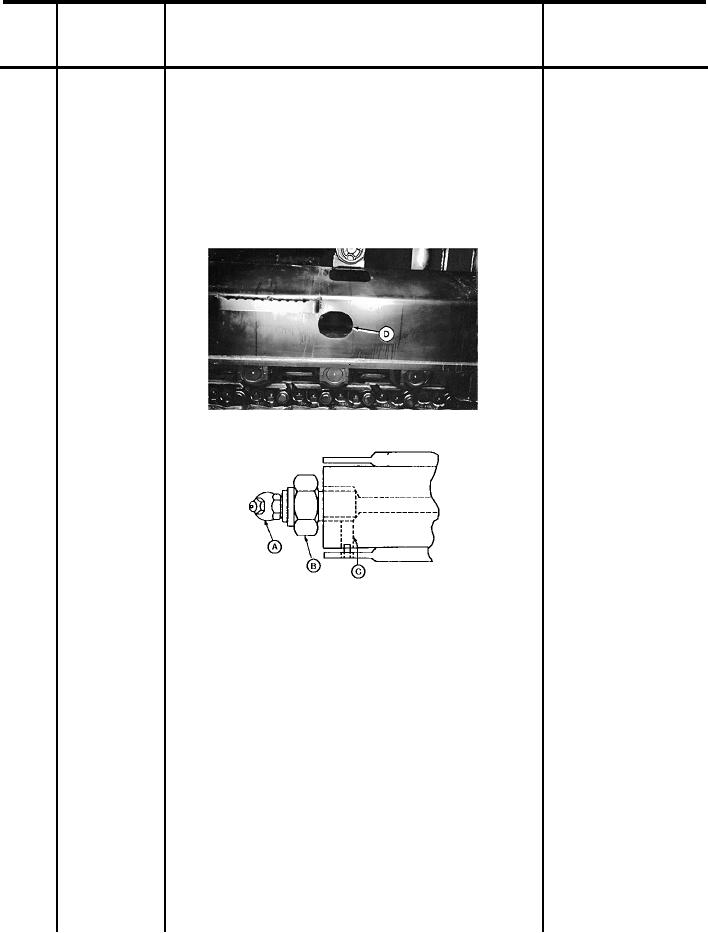

(1) To tighten track, connect grease gun to grease

fitting (A) (located through access hole [D] in

track frame). Add grease until sag is within

specifications (see Fuels and Lubricants,

Chapter 1).

WARNING: Prevent possible injury from

high-pressure grease. Do not remove grease

fitting (A) from nut (B).

(2) To loosen track, slowly turn nut (B)

counterclockwise; grease will escape through

the bleed hole (C).

(3) When track sag is within specifications, torque

Cannot adjust track sag

nut (B) to 147 Nm (108 lb-ft).

TRACK SAG SPECIFICATIONS

Normal Ground Conditions

300--335 mm

(11-13/16--13-3/16 in.)

A-5