TM 5-3805-281-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 330LCR

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

b. The grease must be free of contamination by

dirt and water. If the grease is contaminated,

remove grease and replace with clean

grease.

NOTE: If water or mud is found in swing

gear area, refer to "Operating in Water and

Mud" in the Operating the Machine section.

(3) Add grease as required (approximately 0.113

kg [1/4 lb] every 90) (see Fuels and

Lubricants, Chapter 1).

CAUTION: Excessive grease can damage the

swing gearbox seal.

(4) Remove excessive grease that extrudes over the

top of the swing drive pinion.

(5) Install access cover.

18

Quarterly

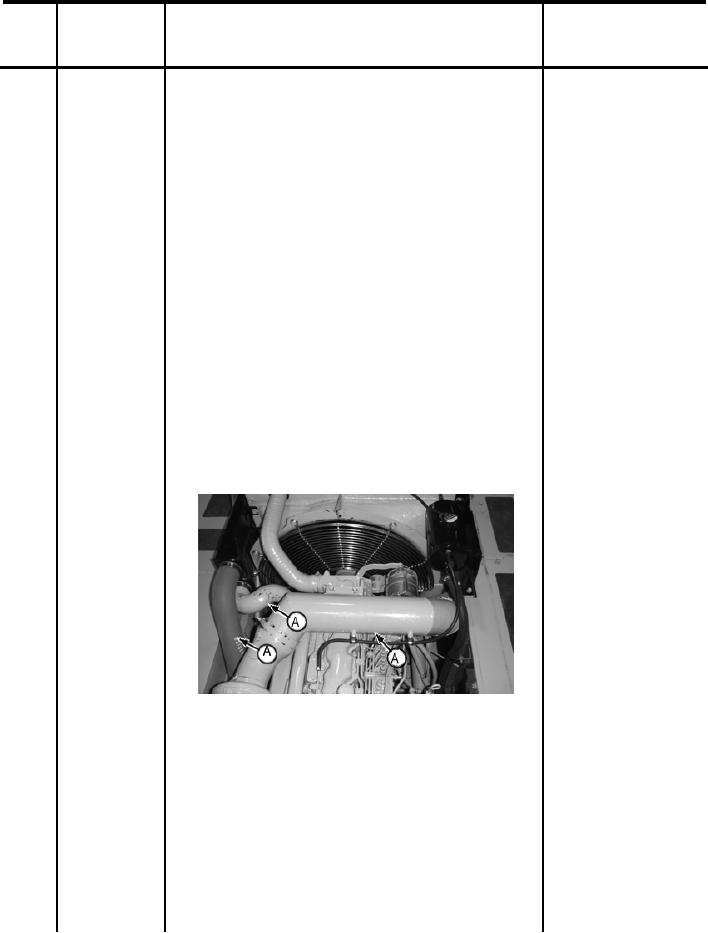

Inspect Air Intake Hoses

(1) Inspect hoses (A) for cracks and leaks. Replace

as necessary.

(2) Tighten clamps.

19

Quarterly

Inspect Breaker Upper and Lower Bushings

(1) Measure upper bushing for wear. Replace if

inside diameter exceeds 158 mm (6.22 in.).

(2) Grease the bushings before reinstalling tool.

(INDECO Supreme 1000 grease or other HD

Moly Grease containing 3 to 5 percent

Molybdenum Disulfide).

A-13