TM 5-3805-294-23-1

0052

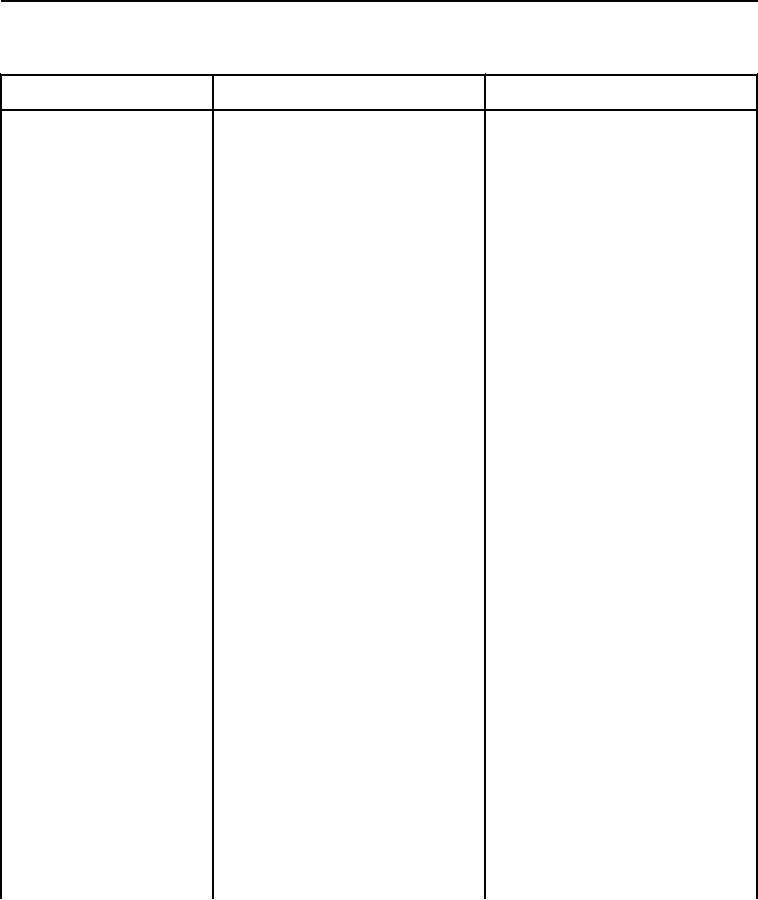

Table 1. DTC 636.02 - High-Pressure Fuel Pump Position Signal Invalid - Continued.

Test or Inspection

Corrective Action

Malfunction

Perform Upper Idler Gear

1.

If not damaged and does not

3.

Webs and Rear

Target Inspection. (Volume 3,

have debris, proceed to

Face On The Upper

Malfunction 4.

Idler Gear Has Burs,

WP 0383)

Chips, or Debris.

2.

If damaged or has debris,

replace engine. (Volume 3,

WP 0410) Restore machine to

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

Visually inspect high-pressure

1.

If damaged or has debris,

4.

High-Pressure Fuel

fuel pump position sensor tip

replace high-pressure fuel

Pump Position

pump position sensor.

Sensor Has

(Volume 3, WP 0435) for

Damage or Debris.

damage or debris.

(Volume 3, WP 0435) If

replacement sensor becomes

damaged, determine cause of

damage. Restore machine to

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

2.

If not damaged and does not

have debris, proceed to

Malfunction 5.

Measure resistance (Volume

1.

If between 2,500 - 3,500 ohms,

5.

High-Pressure Fuel

proceed to Malfunction 6.

Pump Position

3, WP 0369) between pins A

Sensor Faulty.

and B on high-pressure fuel

2.

If not between 2,500 - 3.500

pump position sensor. Note

ohms, replace high-pressure

reading. (Volume 5, WP 0800,

fuel pump position sensor.

Figure 83)

(Volume 3, WP 0435) Restore

machine to original condition

and perform Harness

Diagnostic Mode Test.

(Volume 3, WP 0345)

1.

Install high-pressure fuel pump

6.

ECU Connector J03

position sensor. (Volume 3,

Has Damage or

Loose Pins.

WP 0435)

2.

Disconnect engine wiring

harness connector J03 from

ECU. (Volume 5, WP 0800,

Figure 48)

0052-3