TM 5-3805-294-23-1

0124

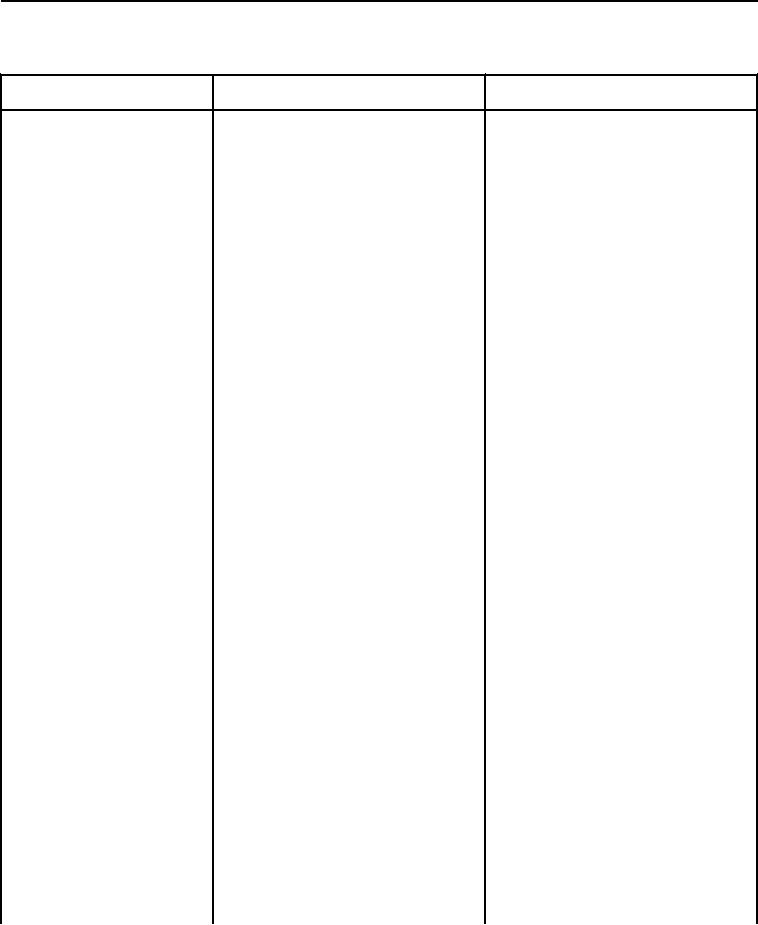

Table 1. Engine Control Unit (ECU) Does Not Communicate With Service Advisor - Continued.

Test or Inspection

Corrective Action

Malfunction

1.

Turn key switch to ON position,

32.

Voltage Between

but DO NOT START ENGINE

ECU 20A F8 Fuse

(TM 5-3805-294-10). (Volume

Socket 2 and

Ground Not Within

5, WP 0794)

1 Volt of Battery

Terminal Voltage.

2.

Measure voltage (Volume 3,

WP 0369) between battery

negative and positive

terminals. (Volume 5,

WP 0800, Figure 5) Note

battery terminal voltage.

3.

Measure voltage (Volume 3,

WP 0369) between ECU 20A

F8 fuse socket 2 (Volume 5,

WP 0800, Figure 154) and a

known good ground. Note

reading.

4.

Turn key switch to OFF

1.

If within 1 volt of battery

position (TM 5-3805-294-10).

terminal voltage, proceed to

Malfunction 33.

(Volume 5, WP 0794)

2.

If not within 1 volt of battery

terminal voltage, proceed to

All 24 VDC Circuits Do Not

Operate. (Volume 2,

WP 0169)

1.

Disconnect engine wiring

33.

Engine Wiring

harness connector J02.

Harness Connector

J02 Has Damage or

(Volume 5, WP 0800, Figure

Loose Sockets.

47)

2.

Visually inspect engine wiring

1.

If damaged or has loose

harness connector J02 for

sockets, repair connector J02

damage and loose sockets.

(Volume 4, WP 0511) or

replace engine interface wiring

harness. (Volume 4,

WP 0509) Restore machine to

original condition.

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 34.

0124-11