TM 5-3805-294-23-1

0124

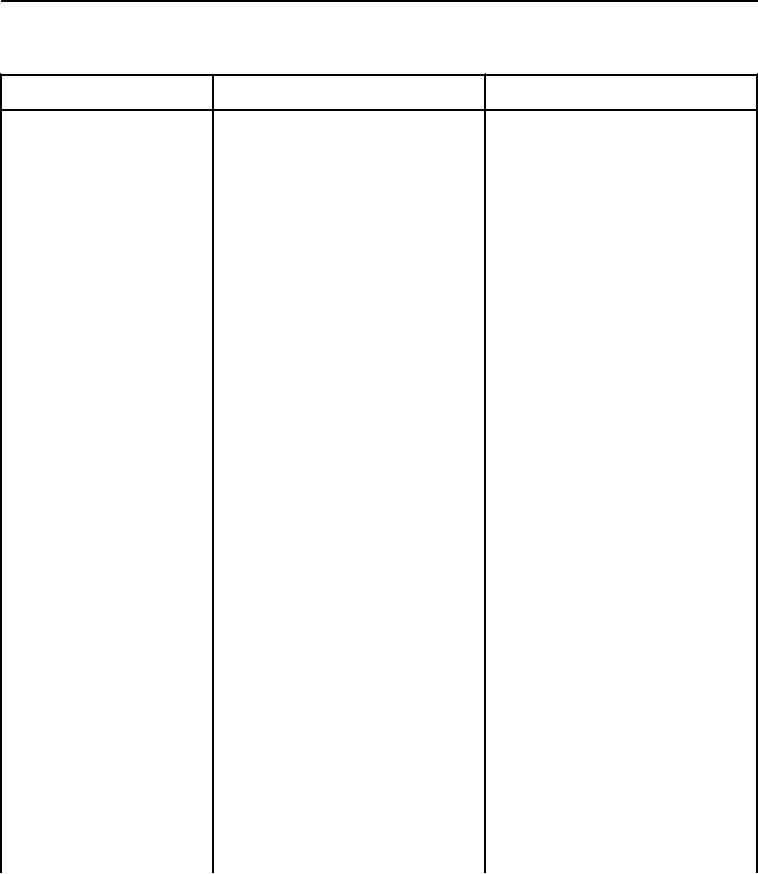

Table 1. Engine Control Unit (ECU) Does Not Communicate With Service Advisor - Continued.

Test or Inspection

Corrective Action

Malfunction

Using jumper wire, measure

1.

If continuity is present, replace

42.

Open Circuit

resistance (Volume 3,

engine interface wiring

Between Connector

harness. (Volume 4,

H02 Pin and ECU

WP 0369) between connector

20A F8 fuse socket

WP 0509) Restore machine to

H02 pin (Volume 5, WP 0800,

1.

original condition.

Figure 41) and ECU 20A F8

fuse socket 1. (Volume 5,

2.

If continuity is not present,

WP 0800, Figure 154) Note

proceed to Malfunction 43.

reading.

1.

Remove center top cover.

43.

Connector X41 Has

Damage or Loose

(Volume 4, WP 0589)

Pins/Sockets.

2.

Disconnect the following:

a. Connector X3. (Volume

5, WP 0800, Figure 84)

b. Connector X4. (Volume

5, WP 0800, Figure 85)

c. Connector X41.

(Volume 5, WP 0800,

Figure 102)

d. Connector X42.

(Volume 5, WP 0800,

Figure 103)

3.

Unmount and reposition the

cab wiring harness connectors

for service. (Volume 3,

WP 0312)

4.

Visually inspect connector X41

1.

If damaged or has loose pins/

for damage and loose pins/

sockets, replace machine

sockets.

wiring harness for socket side

of connector (Volume 4,

WP 0516) or replace cab

wiring harness for pin side of

connector. (Volume 4,

WP 0504) Restore machine to

original condition.

2.

If not damaged and does not

have loose pins/sockets,

proceed to Malfunction 44.

0124-15