TM 5-3805-294-23-1

0124

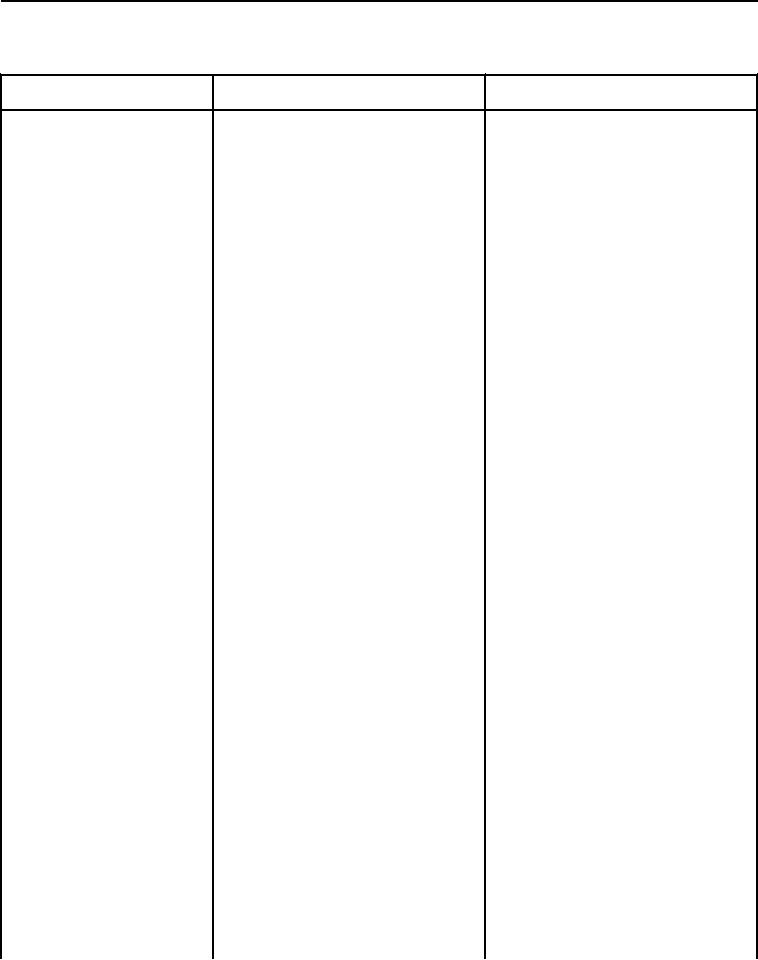

Table 1. Engine Control Unit (ECU) Does Not Communicate With Service Advisor - Continued.

Test or Inspection

Corrective Action

Malfunction

4.

Visually inspect connector X4

1.

If damaged or has loose

for damage or loose sockets/

sockets/pins, replace cab

pins.

wiring harness for socket side

of connector (Volume 4,

WP 0504) or machine wiring

harness for pin side of

connector. (Volume 4,

WP 0516)

2.

If not damaged or does not

have loose sockets/pins,

proceed to Malfunction 51.

Using a jumper wire, measure

1.

If less than 1 kohm, replace

51.

Short Circuit

resistance (Volume 3,

machine wiring harness.

Between Connector

H01 Pin 2 and

WP 0369) between connector

(Volume 4, WP 0516) Restore

Connector X4 Pin

H01 pin 2 (Volume 5,

machine to original condition

29.

WP 0800, Figure 40) and

2.

If greater than 1 kohm, replace

connector X4 pin 29. (Volume

cab wiring harness. (Volume 4,

5, WP 0800, Figure 85) Note

WP 0504) Restore machine to

reading.

original condition.

Measure resistance (Volume

1.

If less than 1 kohm, proceed to

52.

Short Circuit

Malfunction 53.

Between Connector

3, WP 0369) between

X1 Socket D and

connector X1 socket D

2.

If greater than 1 kohm,

Ground.

(Volume 5, WP 0800, Figure

discontinue this

144) and a known good

troubleshooting procedure and

ground. Note reading.

perform DTC 11004.02 as

though DTCs were active.

(Volume 2, WP 0218)

1.

Disconnect engine interface

53.

Short Circuit

wiring harness connector J02

Between Connector

from ECU. (Volume 5,

X1 Socket D and

Ground.

WP 0800, Figure 47)

2.

Disconnect engine interface

wiring harness connector

H01. (Volume 5, WP 0800,

Figure 40)

3.

Measure resistance (Volume

1.

If less than 1 kohm, replace

machine wiring harness.

3, WP 0369) between

connector X1 socket D

(Volume 4, WP 0516) Restore

machine to original condition.

(Volume 5, WP 0800, Figure

144) and a known good

2.

If greater than 1 kohm,

ground. Note reading.

proceed to Malfunction 54.

0124-18