TM 5-2420-230-24-1

Table 3-6. Unit Troubleshooting Table. -- Continued

Malfunction

Test or Inspection

Corrective Action

7.

HIGH OR LOW OIL PRESSURE.

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or tools contact positive electrical circuits, a

direct short may result. Damage to equipment and injury or death to personnel may occur.

Step 1.

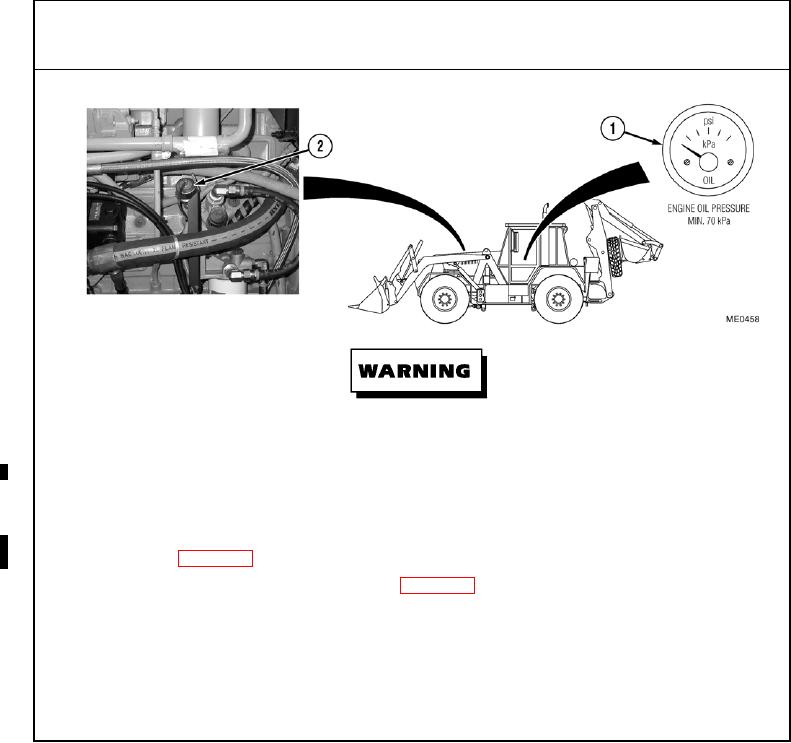

Check ENGINE OIL PRESSURE gauge (1) and oil pressure sensor (2) to ensure both are functioning

correctly.

Remove wire at sending unit and ground to vehicle chassis. Have an assistant watch gauge to identify

its movement. If no movement is noticed, check continuity of wire. Replace wire as necessary

If wire has continuity, replace gauge (Para 12-23).

Step 2.

Check oil pressure regulating valve for correct reading of 30-90 psi (207-621 kPa) at 900 RPM. Clean

valve (Para L-36).

If oil pressure regulating valve is not functioning correctly, replace oil pressure regulating valve

(Para L-36).

If fault continues, notify Direct Support maintenance (Appendix L).

Change 1