TM 5-2420-230-24-1

Table 3-1. Unit Level Preventive Maintenance Checks and Services (PMCS) for IHMEE. -- Continued

Item to be

Checked or

Not Fully Mission

Item

No.

Interval

Serviced

Procedure

Capable If:

14

Semiannual

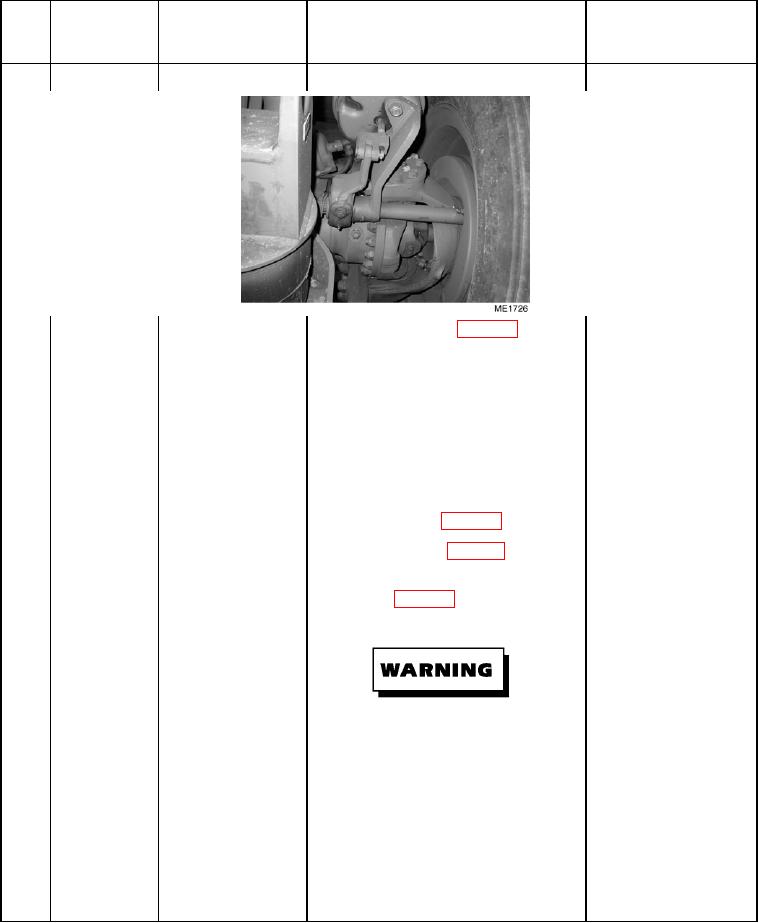

Brake System

a. Remove brake drums (Para 8-6).

b. Check that brake shoe linings are not worn Brake shoe linings are less

to less than 0.3 in. (8 mm).

than 0.3 in. (8 mm) thick.

c. Inspect brake shoe linings for oil

Oil contamination or

contamination and damage.

damage is evident.

d. Check brake drums for obvious grooves

Deep grooves or uneven

and uneven wear.

wear is evident.

e. Clean hub and brake shoe assemblies with

degreasing solvent (Para 8-6).

f. Install brake drums (Para 8-6).

g. Inspect slack adjuster for damage and

Slack adjuster is damaged

adjustment (Para 8-6).

or brake shoes can not be

adjusted.

15

Semiannual

Exhaust System

Hot parts can burn personnel. Let hot parts

cool before starting work.

Evidence of excessive

corrosion or carbon

and tailpipe for corrosion and carbon

deposits.

deposits which may indicate leaks.

Pipes or clamps are

b. Inspect exhaust system for damaged or

loose pipes or clamps, and leaking gaskets damaged, clamps are loose,

or gaskets or seals are

or seals.

leaking.

3-12