TM 5-2420-230-24-1

8-6. BRAKE DRUM REPLACEMENT.

This Task Covers:

a. Removal

b. Cleaning

c. Inspection

d. Installation

e. Adjustment

f. Testing

g. Follow-On Maintenance

INITIAL SETUP

Test Equipment

References

None

TM 9-214

TM 9-2610-200-14

Tools and Special Tools

Tool kit, common no. 2, Item 36, Appendix B

Equipment Conditions

Tool kit, general mechanics, Item 38, Appendix B

TM or Para

Condition Description

Wheel and tire removed.

Materials/Parts

Cloth, lint-free, Item 10, Appendix C

Drawings Required

CRC 5-56, Item 40, Appendix C

TM 5-2420-230-24P Figure 101

Solvent, degreasing, Item 58, Appendix C

TM 5-2420-230-24P Figure 103

Personnel Required

Estimated Time to Complete

MOS 62B, Construction Equipment Repairer (2)

Refer to MAC in Appendix B

NOTE

Maintenance procedures are shown for one

brake drum only, but are performed the

same way for all wheels.

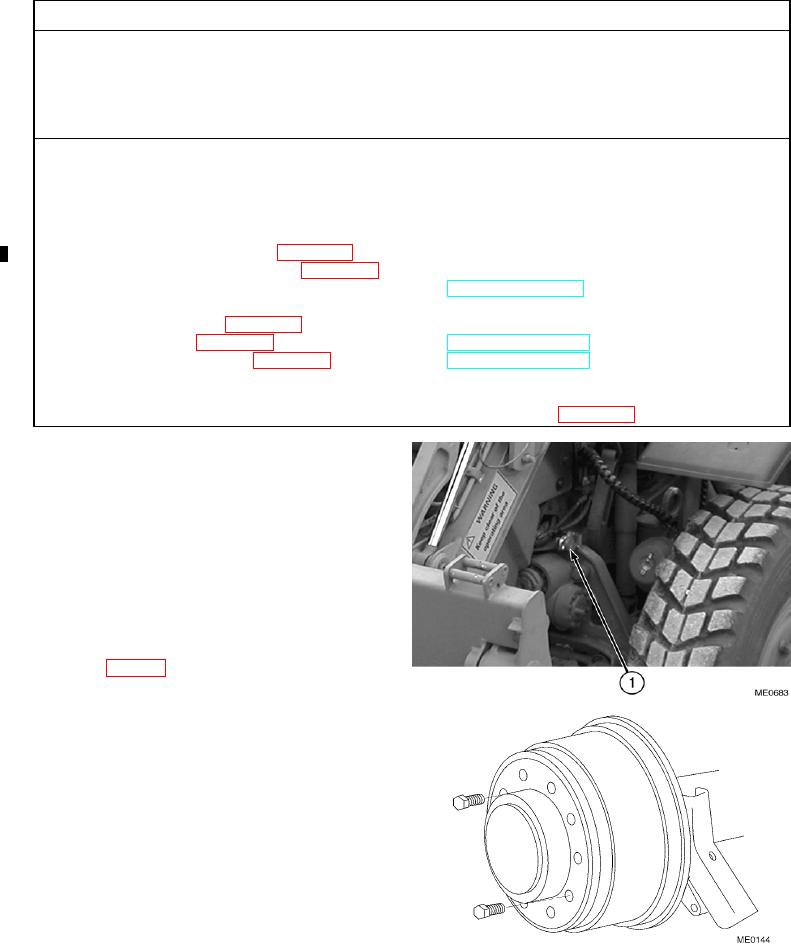

a. Removal.

(1)

Release parking brake control. If there is

insufficient air in air tanks, connect external

air source to front, left glad hand fitting (1)

or manually cage spring brake chamber

(2)

Rotate brake drum and ensure it rotates

freely without binding on brake shoes.

(3)

Remove all paint from hub with wire brush

and lubricate with CRC 5-56.

(4)

Remove retaining screw from brake drum to

axle hub.

(5)

Install two setscrews into both of tapped

holes until tight. Equally tighten both screws

to remove brake drum.

Change 1