TM 5-2420-230-24-1

BRAKING SYSTEM

Contents

Para

Page

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Operation - Basic Operation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vehicle Preparation and Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restore IHMEE to Operational Readiness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slack Adjuster Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Drum Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spring Brake Chamber Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spring Brake Chamber Caging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foot Treadle Valve Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake Control Replacement.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This section contains procedures that relate to

maintenance activities detailed in Chapter 3, Preventive

Maintenance Checks and Services (PMCS). This chapter

should be read in conjunction with Appendix J.

Components covered within this section include:

Brake drum and mechanism

Brake mechanism adjustment

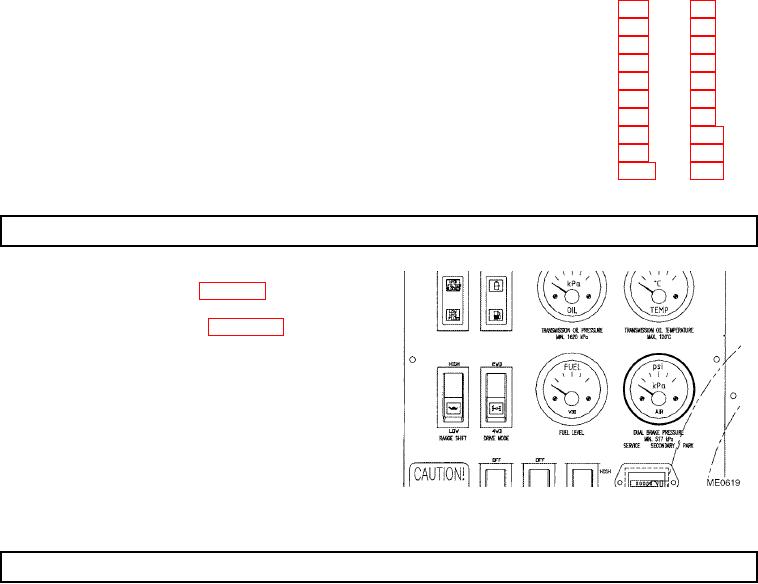

The DUAL BRAKE PRESSURE gauge has two

pointers, one white and one green. The white pointer is

for service air and the green pointer is for park/secondary

air.

8-2. SYSTEM OPERATION - BASIC OPERATION.

a. General. The brake system consists of four spring brake chambers, with one at each wheel. The engine-driven

compressor has an integral governor set at 119 psi (820 kPa).

b. Primary System. When the foot brake pedal is depressed, air pressure is directed from the reservoirs, through the foot

valve, to the spring brake chambers. Air pressure acts on the pneumatic diaphragm, which pushes the chamber rod. The

chamber rod is connected to the slack adjuster and a shaft. This shaft operates the S-cam, which in turn brings the brake

linings into contact with the brake drum, thus providing braking action.

The amount of braking action is directly proportional to the amount of effort applied to the foot brake pedal. As more

pressure is applied to the foot brake pedal, more air pressure is directed to the brake chambers, and more braking action

is applied to the vehicle. The system is provided with a pressure-reducing valve to prevent rear wheel lockup due to

weight transfer as the brakes are applied.