TM 5-2420-230-24-2

Piston and Rod Assemblies - Installation (0-72)

Section 0 - Engine Disassembly and Assembly - Group 00

Page 0-48

B Series Shop Manual

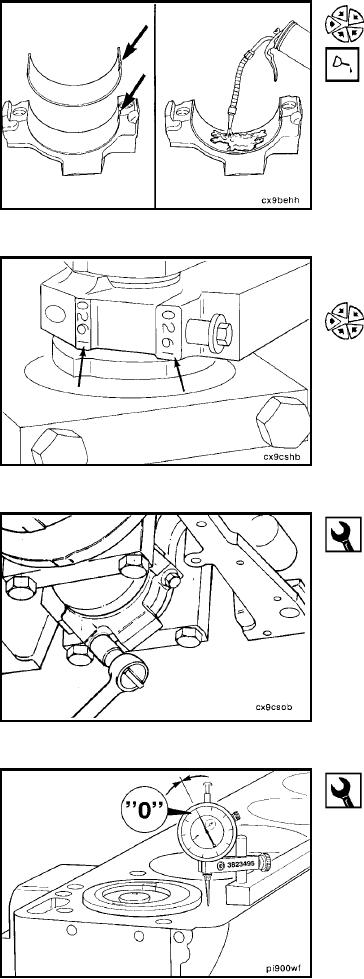

Install the bearing shell in the connecting rod cap with the

tang of the bearing in the slot to the cap.

Use clean lubricating oil to coat the inside diameter of the

bearing shell.

The four digit number stamped on the connecting rod and

cap at the parting line must match and be installed on the

oil cooler side of the engine.

Install the connecting rod cap and capscrews to the con-

necting rod.

12 mm, Torque Wrench

Tighten the two capscrews.

Torque Value: 35 Nn

[26 ft-lb]

3823495 Dial Indicator

Use a fine grit stone to remove any burrs from the cylinder

block head deck.

Zero ``0'' the dial indicator to the cylinder block head

deck.

L-137