TM 5-2420-230-24-2

Section 0 - Engine Disassembly and Assembly - Group 00

Crankshaft - Installation (0-71)

B Series Shop Manual

Page 0-45

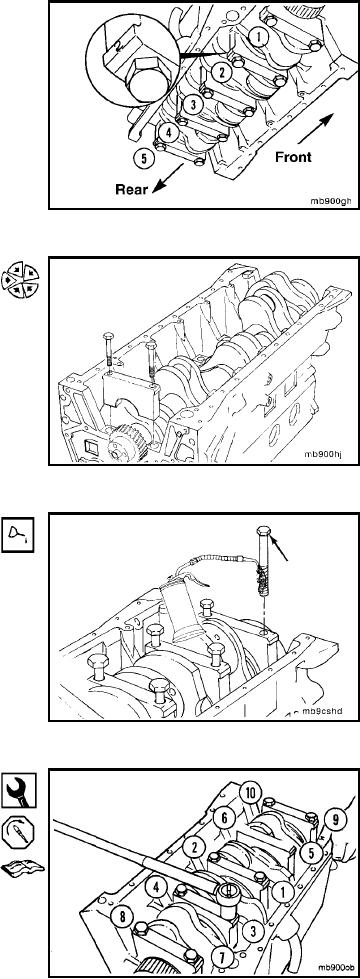

The main bearing caps are numbered for location. Num-

ber 1 starts with the front of the block, and the numbers

face the oil cooler side of the engine.

Position the main bearings and caps.

Lubricate the main bearing capscrew threads and un-

derside of the head with clean engine oil.

23 mm

Tighten the capscrews evenly following the illustrated

sequence.

NOTE: When the engine is equipped with a balancer the

main bearing caps cannot be torqued until the piston and rod

assemblies are installed. It is also necessary to establish Top

Dead Center before the balances can be installed. If a bal-

ancer is to be installed at a later procedure install and tighten

No. 2, 3, and 5 main bearing capscrews until the main

bearing caps are seated and proceed to procedure (0-72).

L-134