TM 5-2420-230-24-2

Section 0 - Engine Disassembly and Assembly - Group 00

Piston and Rod Assemblies - Installation (0-72)

B Series Shop Manual

Page 0-53

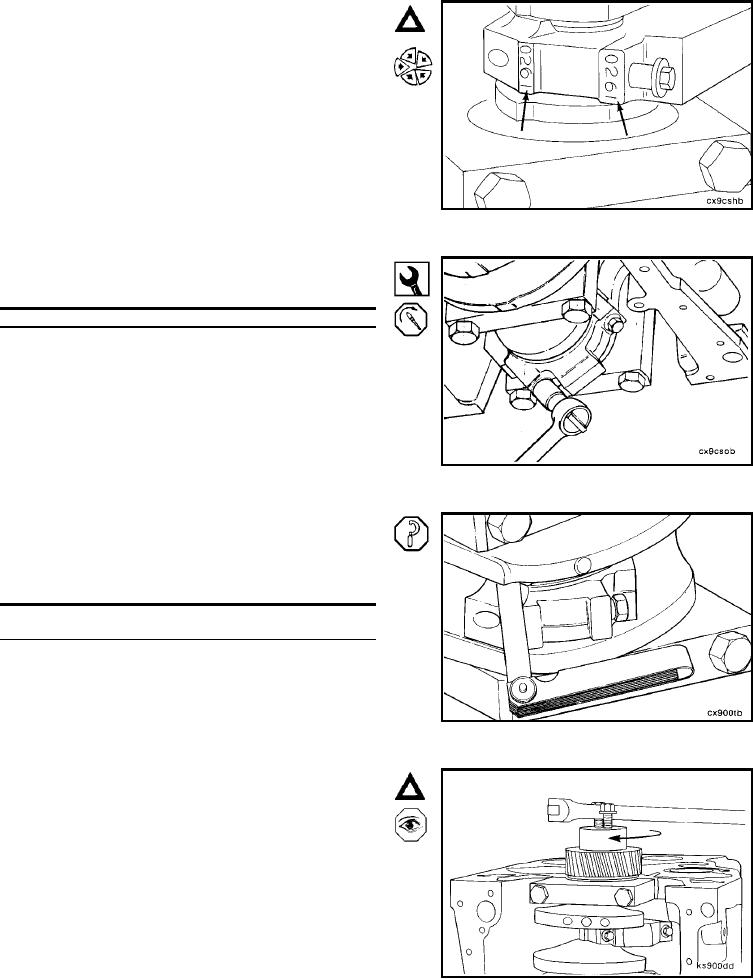

Caution: The four digit number stamped on the rod and

the cap at the parting line must match and be installed

on the oil cooler side of the engine.

Install the rod cap and capscrews to the connecting rod.

12 mm, Torque Wrench

Alternately, tighten the two capscrews

Step

Torque Value

1

35 Nm [26 ft-lb]

2

70 Nm [52 ft-lb]

3

100 Nm [74 ft-lb]

Measure the side clearance between the connecting rod

and crankshaft.

Do not measure the clearance between the rod cap

and crankshaft.

Side Clearance Limits

mm

in

0.10

MIN

0.004

0.30

MAX

0.012

Caution: The crankshaft must rotate freely.

Check for freedom of rotation as the rod caps are in-

stalled. If the crankshaft does not rotate freely, check the

installation of the rod bearings and the bearing size.

L-142