TM 5-2420-230-24-2

Section 16 - Mounting Adaptations - Group 16

Flywheel and Ring Gear Inspection (16-01)

B Series Shop Manual

Page 16-3

Flywheel and Ring Gear Inspection

(16-01)

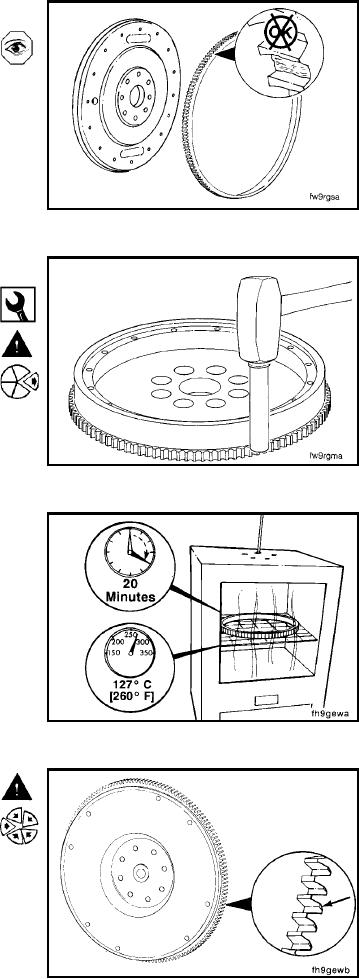

Check the ring gear teeth for wear or damage. Use the

dye penetrant method to check the mounting holes for

cracks. Check the clutch face surface for cracks or dam-

age. If equipped with a flexplate, check the flexplate for

cracks or damage.

NOTE: If the ring gear teeth are worn or damged, the ring

gear must be replaced.

Ring Gear Replacement (16-02)

Brass Drift Pin

Warning: Wear eye protection when you drive the gear

from the flywheel. Do not use a steel drift pin.

Use the drift pin to drive the ring gear from the flywheel.

NOTE: The ring gear on flexplate applications cannot be

replaced as a separate unit. The entire flexplate assembly

must be replaced.

Heat the new ring gear for 20 minutes in an oven pre-

heated to 127C [260F].

Warning: Wear protective gloves when you install the

heated gear.

Install the gear. The gear must be installed so the bevel

on the teeth is toward the crankshaft side of the flywheel.

L-471