TM 5-2420-230-24-2

Cylinder Block (001-026)

B3.9 and B5.9 Series Engines

Page 1-64

Section 1 - Cylinder Block - Group 01

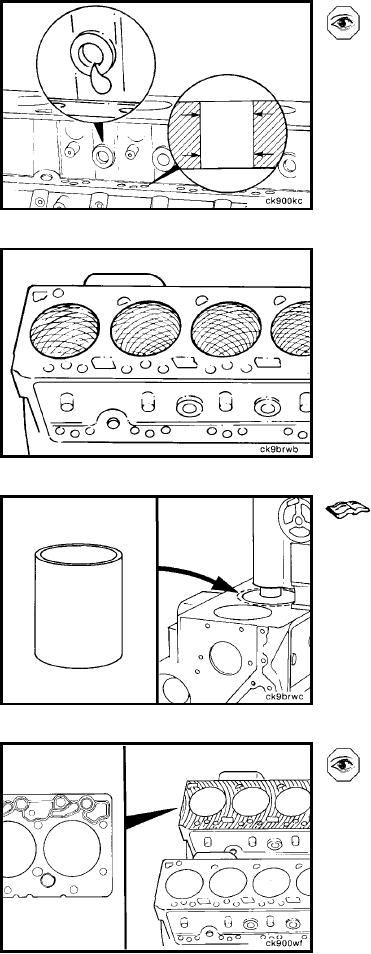

Malfunctions of the cylinder block, such as leaks, tappet

bore wear, etc, require a visual or dimensional inspection

to isolate the problem.

The cylinder bores are machined directly into the cylinder

block during production. The size and condition of the

cylinder bore is critical to engine performance and life.

During repair, be sure to inspect the cylinder bore carefully.

It will also be necessary to deglaze the cylinder walls before

reassembly. A 30-degree crosshatch pattern is needed to

seat the new piston rings.

The cylinder bores can be rebored in a machine shop and

fitted with an oversize service piston. The cylinder bore can

also be bored to accept a service liner and standard pis-

tons. Refer to the B Series Alternative Repair Manual,

Bulletin No. 3810234, for rebore procedures.

NOTE: The head surface of the block is also critical to

sealing the cylinder bores. Inspect the surface carefully

during repair before assembly. The cylinder head deck can

be resurfaced in a machine shop and a thicker surface

cylinder head gasket installed to keep the piston-to-head

clearance the same.

L-742